Rubbing Tester Mastery: A Comprehensive Guide

You know, check out the rubbing tester. It's a extremely important tool for figuring out how material substances stand up to use and abuse. Within this little manual, we're gonna explore five most common questions about the rubbing tester. We'll present the information and offer some advice to help you grasp the concept.

What's the deal with a rubbing tester, anyway?

Now, how does this rubbing tester actually work?

So, what are the different kinds of rubbing testers out there?

So, how do you pick the right rubbing tester for what you need?

Now, where do you find a good supplier for these rubbing testers?

The rubbing tester is a essential tool in materials science and engineering field, designed to imitate the wear that materials experience in actual use scenarios. It's all about testing how materials can endure friction and abrasion, making sure they last and function effectively in different places.

So, one big thing the rubbing tester does is evaluate the resistance of fabrics, paints, and coatings to wear. They subject these materials to a controlled wear test to see if they're suitable for the task. Like, say you're picking out paint for a car, a rubbing tester can help you choose a product that will not chip or fade when it's exposed to the outdoor conditions.

And it's also an important aspect of material testing for automotive interiors. They test stuff like vehicle seats, door trim, and dashboard materials to make sure they maintain their quality over time and remain visually appealing.

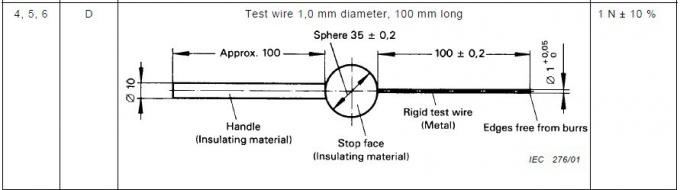

It usually has a rotary drum or a flat plate that slides against the material. You can adjust the force and speed to simulate various wear scenarios. Then it determines how much material gets eroded after a set number of cycles.

The Taber Abrasive Tester is a popular one, with a circular drum that's got these abrasive heads on it. You put the material inside the drum, and it spins at a constant speed while the abrasive heads move over the surface. Then they measure how much material gets eroded to see how resistant it is to wear.

You gotta ensure the details are correct, like the weight and the speed, to ensure precise outcomes. You can modify these settings based on the test and how you intend to apply it.

There are several of various types, each created for particular uses and materials. The main ones are the type of TaberAbraser, Durometertype test, and the Martindale type abrader.

The type of TaberAbraser is a big deal for assessing the durability of substances such as paint, finishing coat, and synthetic materials. Durometertype test is primarily concerned with gauging the hardness of materials like elastomers and synthetic materials. The Martindale type abrader is generally used for evaluating textiles and leathers to determine their resilience against wear and tear.

Each testing device each features its own specific criteria and guidelines, therefore, it is crucial to select the most appropriate one concerning the material and the purpose of its use. For such as, if you're testing a automotive finish, a type of TaberAbraser typically, this is the appropriate choice.

Consider these factors several aspects while selecting a testing equipment, like which material you are evaluating, the intended purpose of the test, and the nature of the abrasion that it will experience.

For instance If you are testing the material, you desire a tester that can imitate the abrasion it will experience in the car. Or say you're testing paint on outdoor furniture. You need a tester that can simulate the really tough conditions, like UV rays and severe temperatures.

Moreover, you should consider the ease of use and care of the tester. Some testers can be a pain to calibrate or maintain, which can be cumbersome and increase your expenses and time. Obtaining a tester that is user-friendly and low-care can conserve your time and resources over time.

It is important to purchase your tester from a trusted supplier to ensure it is of high quality and precision. A variety of reliable suppliers and producers offer diverse models and accessories.

The Taber Company is a reliable source, known for its quality equipment for wear resistance testing. Another excellent option is the Instron Company, which has a range of testing machinery, including rubbing testers, for various substances and uses.

Always ensure to compare the characteristics, specifications, and costs from various vendors before making a purchase. Examining comments and asking other experts for recommendations can also give you useful information on how dependable and efficient various testing devices are.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- ISO 80369-3 Test Equipment LIst

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability