When Precision Meets Power: The Accelerated Mechanical Shock Tester's Unmatched Performance

Yo, being an engineer who deals with stuff like tests for stuff, I've totally used these innovative devices. They're like time machines for testing, showing us how objects will withstand under everyday madness. Okay, I figure let's jump into some top stuff about this awesome thing and maybe tell people what it's about from my standpoint.

1. So what makes an accelerated mechanical shock tester so bad-ass? What cool stuff can it do?

2. How does this guy help cut out the fluff and streamline testing of materials quicker?

4. What if we apply the power-ups in aerospace to cars that cruise the streets everyday?

5. What are the limitations of an accelerated mechanical shock tester?

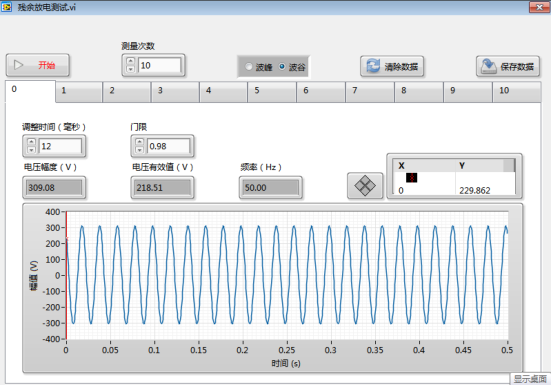

My first encounter with an accelerated mechanical shock tester was a revelation. These devices are designed with precision and strength in mind, featuring high-speed shock generation capabilities, complex control systems, and reliable data acquisition systems.

Spent some time interacting with these tester devices. Witnessed firsthand? Those guys can generate shock waves effectively at various speeds and intensities, testing those materials thoroughly, I should say. The key features include a high-definition touch screen, instantaneous data monitoring, and the customizable test parameter settings, which is crucial for precise outcomes.

Efficient is your name on testing. This gizmo? Changes the rules when we're talking about time crunches. Through replicating environmental conditions, these testers can rapidly discern material weaknesses, conserving time and resources.

In contrast to those slow-paced traditional tests, it is extremely fast. A significant noticeable difference that's easy to point out! Sure, there are a lot of numbers floating around, but with that tester data? The engineers, they’re moving mountains faster, Due to highly precise data. Moreover, the shock tester is capable of conducting several tests concurrently, even more improving efficiency.

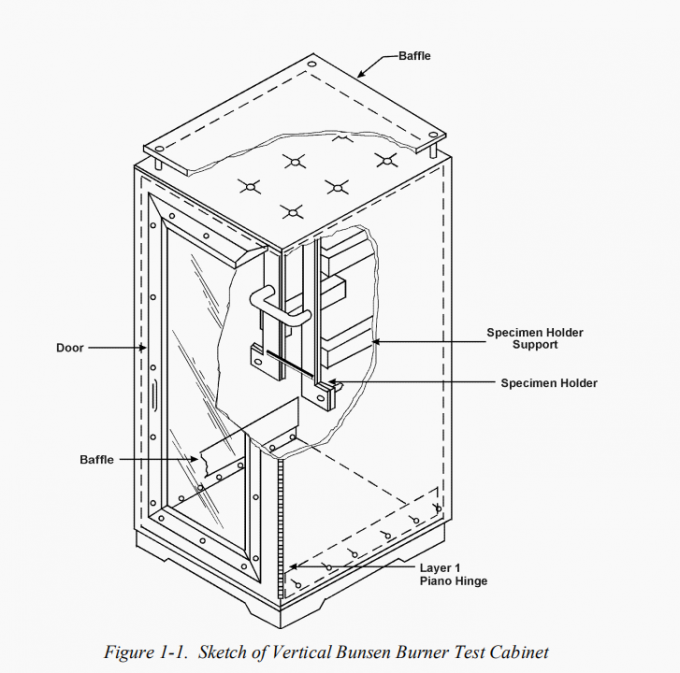

Mate, our group and I? We were experienced in aerospace, and this shock machine was the key component that made every mix is successful. In aerospace, materials must withstand severe environments, and the shock tester is ideal for this use.

It enables us to test materials for their resistance to shock and vibration, which is vital for the safety and operation of aerospace parts. We've seen firsthand how the shock tester helps us identify potential issues early in the development phase, preventing expensive and lengthy setbacks.

Vehicles! There's so much about that sector where shock testing greatly improves them - from their structures all the way to components that are hard to see from an airplane. In the vehicle manufacturing industry, materials must be sturdy and able to handle shocks and vibrations, and the shock tester ensures we comply with this.

I've utilized the tester to test the resilience of materials employed in car bodies, tyres, and suspension units. I was almost able to hear the cars were singing about how they loved it – the entire game of automobile safety, performance was enhanced because we used these shock absorbing devices. They just made vehicles better by testing stuff.

No device is perfect, amirite? Let's be truthful about this with a few limitations. And here comes the limit - these devices have a specific purpose where they aren't designed for anything unusual on shock simulations, they are mainly focused on a task for one specific sort of impact and vibrato, right?

For more intricate testing situations, extra equipment might be necessary. And let's be straightforward: they are certainly not cheap, this shock tester gang. Prices can soar upwards than a stock market like at peak times. Okay, you pay 'em but, hell, those advantages to the tasks these testers perform for materials testing—definitely justifies the investment, I'd say.

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

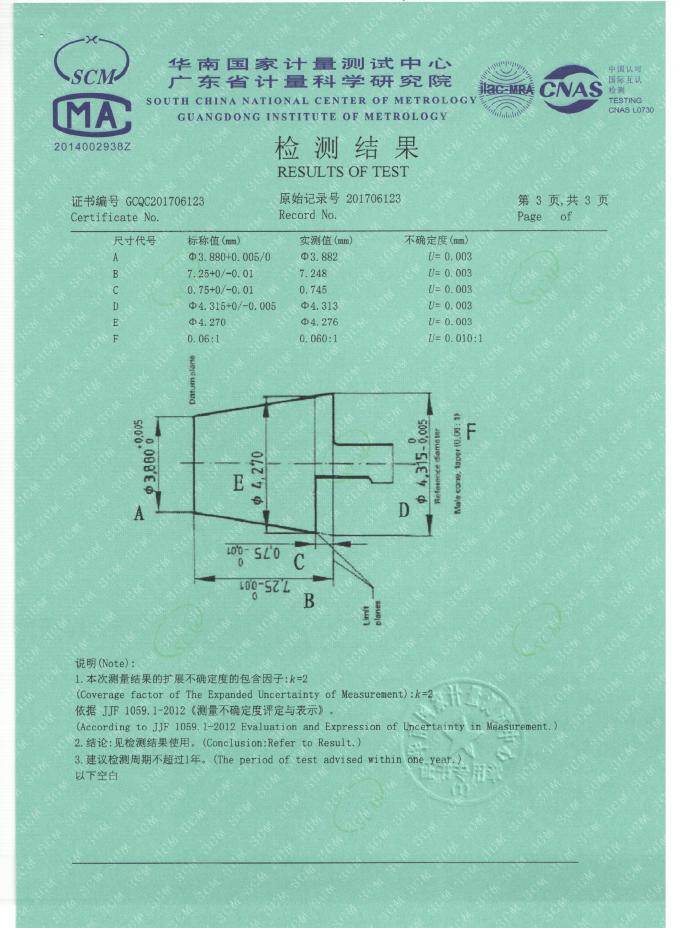

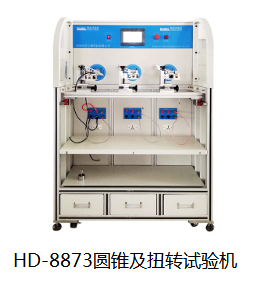

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability