Visit the World of Impulse Withstand Voltage Testing

Being an electronics engineer, I've seen how impulse withstand voltage testing has evolved over time. It's really cool. It makes sure that electronics devices are reliable and safe. So, today, we're gonna dive into the detailed aspects of this testing, like how it operates and applications of it.

AC and DC Impulse Voltage Testers

Now, dielectric failure is a big deal in this testing. It's when a material can't take the voltage stress anymore and starts to conduct electricity.

It helps us figure out if the the materials we use for high-voltage applications are holding up well. I remember my first big project was testing this new insulating material for really high-voltage transmission lines. And the material was awesome, doing great even under severe conditions.

You need these high-voltage pulse generators. They are essential for this testing field. They produce these brief, high-voltage pulses to simulate what electrical components have to endure when they are operating properly.

Our team and I developed this innovative pulse generator, which significantly improved our testing efficiency and accuracy. This has been beneficial for our clients, because it is enabling them to bring their products to market quicker with higher quality.

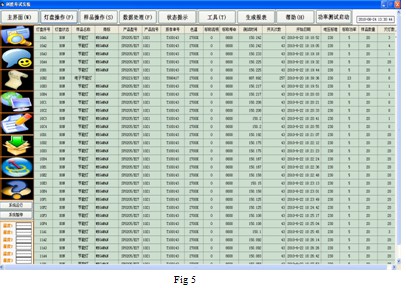

Furthermore, there are these AC and DC testers which we frequently use for testing These devices produce these AC and DC pulses to simulate what the devices might encounter in the real world

We have employed these testers to investigate how various devices deal with different voltages, which has been quite useful. This has assisted our clients in identifying potential failures in their gadgets and correct issues before they reach the market.

The Institute of Electrical as well as Electronics Engineers as well as International Electrotechnical Commission have these really rigid guidelines for evaluation. Following these guidelines guarantees the dependability as well as stability of our evaluations.

We have some renown for really being knowledgeable about how to do this evaluation stuff correctly. This has been enabled us to offer exceptional support to customers in industries like aviation as well as space, automotive, as well as mobile devices.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment