High Voltage Impulse Test: Understanding Its Significance

In electrical engineering field, high voltage impulse tests are super important. They make sure our voltage equipment is safe and dependable. These tests are like a simulation of lightning strikes incidents and other electrical disruptions. They check how well components and infrastructures can protect against those tests. We're gonna explore in depth five big questions about high voltage impulse tests. We'll share some actual incident reports and give you the lowdown to make our insights more believable.

So, what's the deal with high voltage impulse testing, anyway?

How do they actually run these high voltage impulse tests?

There are different kinds of high voltage impulse tests, right? Let's talk about them.

Are we talking about safety when we do these high voltage tests?

What's the good stuff we get from high voltage impulse testing?

High voltage impulse testing is mainly about seeing if materials and systems can handle a abrupt, extremely high voltage surge. These tests can spot vulnerable areas in insulation that could damage equipment or pose a risk. By making our gear act like it's getting hit by lightning or dealing with other electrical zaps, designers ensure their designs are robust and secure for daily operation.

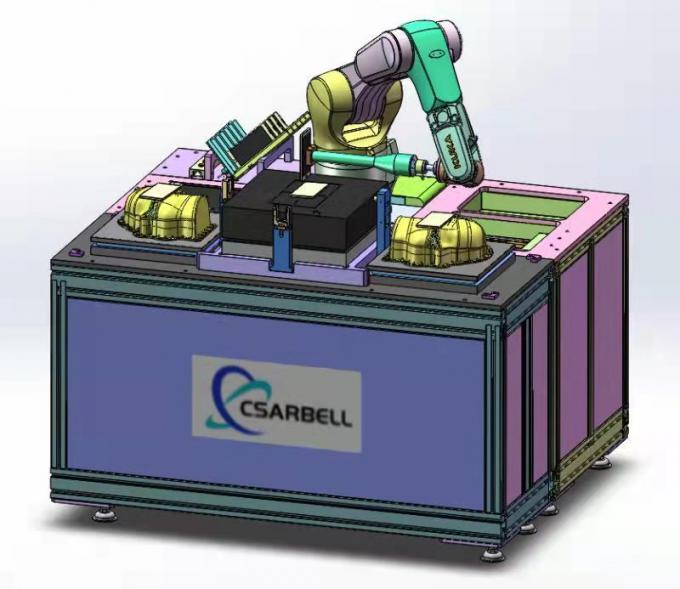

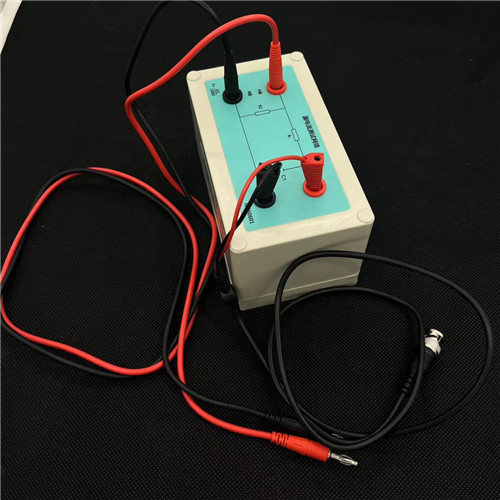

They do a high voltage impulse test by sending a brief, high-voltage surge to the material or system they're testing. They usually use a specific device called an impulse generator to make the zap with just correct voltage and current levels.

The testing configuration has a large transformer, a surge generator unit, and a recording device how the material or system responds during the test. After the test, they look at the results to evaluate performance the material or system held up.

There are different types of high voltage impulse tests, each one examining various aspects of insulation and protection. Some commonly used methods are the common impulse test, the lightning flash impulse test, and the transient impulse test.

The routine impulse test is used to measure the insulating resistance of a material, while the lightning stroke simulation test resembles the impact of a lightning strike. The make-up impulse test looks at how insulation holds up against voltage spikes from switching.

Extreme caution must be exercised when doing high voltage impulse tests in order to prevent incidents and harm. These tests can be dangerous because they operating at significantly high voltages, so you need to use appropriate personal protective equipment and adhere to safety protocols. Furthermore, you must ensure the equipment is properly properly grounded to suppress any electrical arcs and ensure the safety of all personnel.

High voltage impulse testing is great because it makes increasing safety of things, enhancing reliability, and improved performance. By means of identifying weaknesses withwithwithin the insulating material system, engineers are able to rectify issues to prevent equipment failure and enhance safety. And This testing process ensure the equipment satisfies all relevant industry regulations, therefore it is suitable for a wide variety of applications.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability