Best Impulse Winding Tester Insights

Ever think about how those devices work? These devices are extremely crucial for ensuring motors and transformers operate correctly. In this article, I'm going to explore how the testers function and address various frequently asked inquiries.

What's up with an impulse winding tester, you ask?

So, how does that tester gadget work?

Why is this insulation testing stuff important?

What are the tricky parts about doing this insulation testing?

How do you pick the right tester gadget?

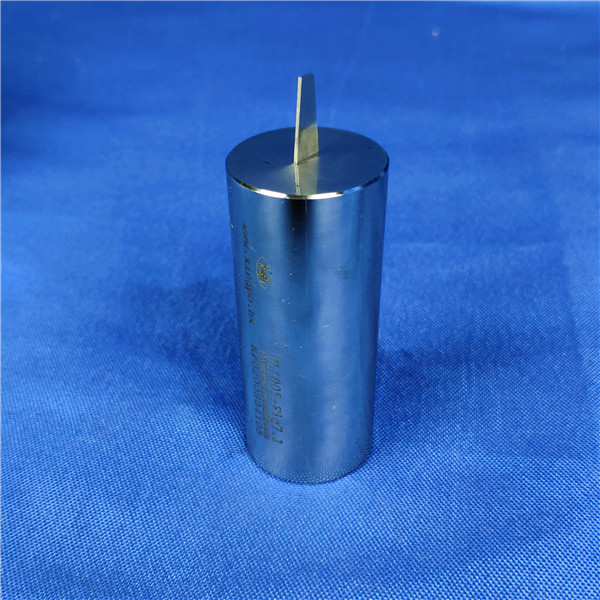

An sheathing tester is a tool that checks how well the sheathing in cables resists electricity surge. It's super critical for ensuring engines and devices are secure and reliable. The tester provides the coiling a brief surge of electricity surge and subsequently records the electrical flow. It facilitates calculate if the sheathing is in good condition.

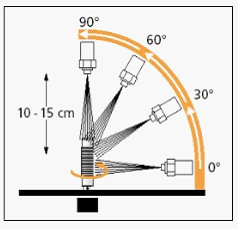

The tester zaps the coiling with a high-electricity electricity spike. That electric shock creates an intense amperage that circulates through the coiling.

The tester subsequently records the sheathing through monitoring the amount of amperage passes and deducing the impedance. If the sheathing is failing, it could indicate a indication that an issue exists with the cable.

There are a lot of valid motivations to do this insulation testing. It spots potential problems with the insulation that could cause power problems or be hazardous. It also makes sure that the motor or transformer is hitting the right insulation standards to keep it reliable and durable.

One major challenge is getting reliable results. It can be tricky because of factors like temperature, humidity, and the state of the wire itself. Another tricky part is interpreting the measurement outcomes right because they can be influenced by a several variables.

Picking the right tester involves looking at factors like the wire type, the voltage it needs, and the evaluation criteria. You gotta pick a tester that's most suitable for your requirements and meets all safety considerations and accuracy factors.

So, there is your answer—a brief look into the realm of impulse winding testing devices and the concept. I wish this piece resolved some uncertainties you could have possessed regarding these crucial testing tools.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- ISO 80369-7 Luer Gauge Checklist

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment