Coupon Impulse: Navigating Insulator Tests

So, as someone who operates with electrical insulating material, I'm always deep into the nitty-gritty of it process called impulse testing of insulators. It procedure is super crucial for maintaining power systems dependable and secure. So, I'm planning to delve into five major questions about it matter, and I'll contribute some of my own insights and opinions on it.

What's this 'impulse testing of insulators' all about?

How does this impulse testing thing actually work?

Why is impulse testing such a big deal?

What can mess with the results of impulse testing?

How do you make sense of those impulse testing results?

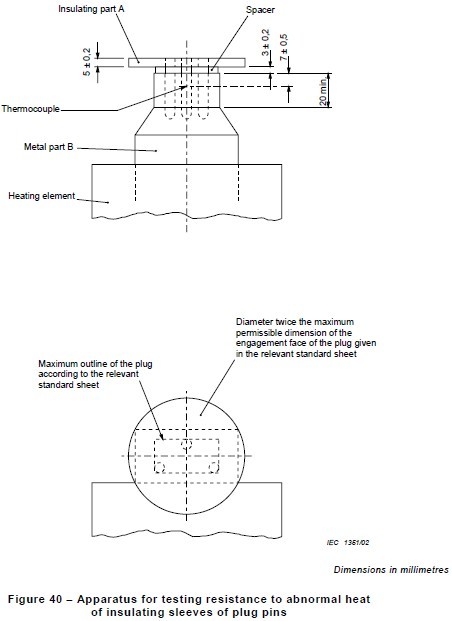

Impulse testing is a way to determine how strong and solid insulating substances are. They shock the material with a big blow of electricity really fast to see if it can cope with a surge. This test helps spot any weak spots in insulators that might cause big problems in electrical systems.

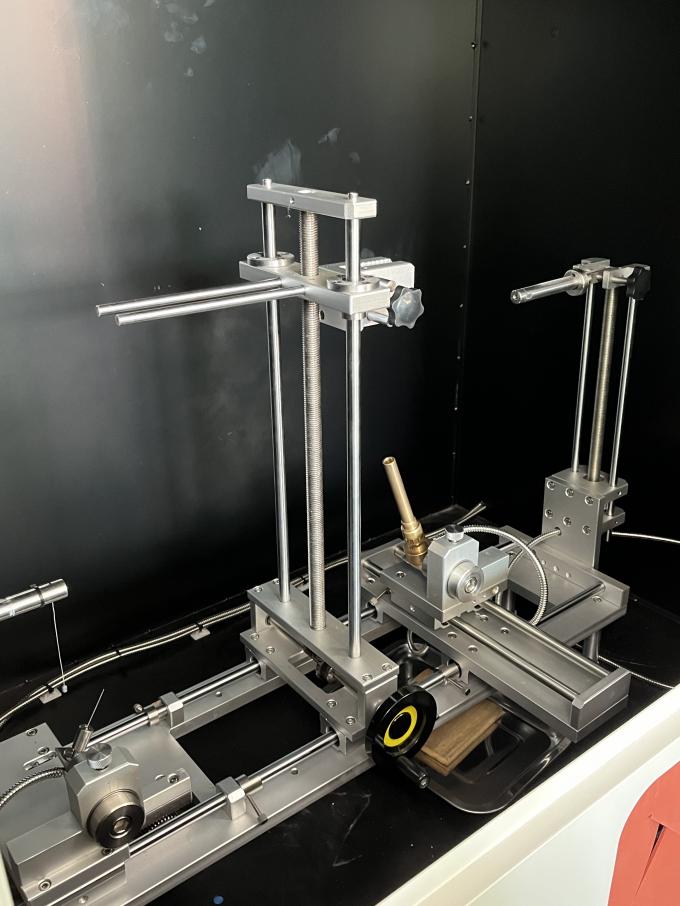

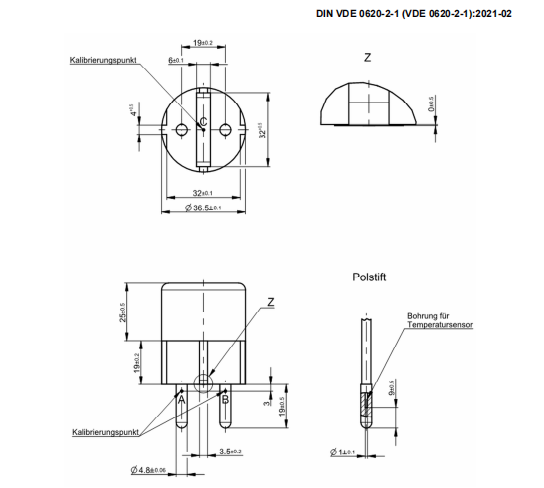

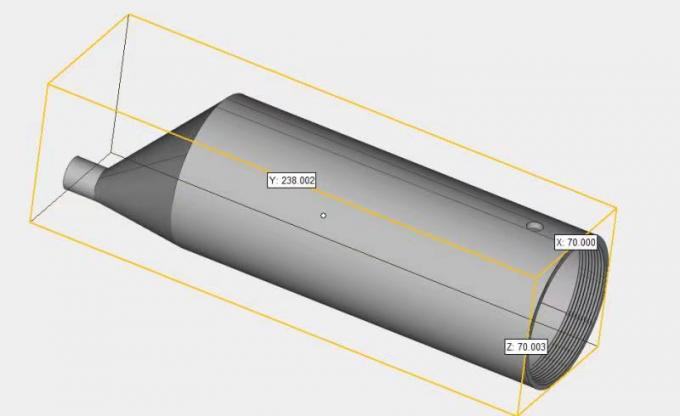

They use this high-electricity device to shock the insulator with a big electricity spike. They usually set up a test with a high-electricity transformer, a surge producer, and a special test loop.

They hook up the insulator to the loop and then shock it with the impulse. They do this shock thing a bunch of repetitions to make sure it's consistent and accurate. After that, they look at the outputs to see how effectively the insulator can cope with electricity peaks.

Surge testing is crucial for keeping power systems safe and trustworthy. This test identifies defects in insulation materials, which prevents power issues, equipment damage, and fires outbreaks. It Moreover assists manufacturers and designers select the appropriate insulative materials for their products, which enables the system to perform more effectively and have a longer lifespan.

Several factors can interfere with the results of Surge testing. That's stuff like the material of the insulation, the setup process the experiment, and the surrounding conditions in which it is performed.

You must maintain these aspects under control in order to ensure the experiment results are reliable and trustworthy. Moreover, the duration and form of the insulation can affect how the experiment turns out.

Figuring out the results of impulse testing is about looking at the data from the test, like the breakdown voltage and how many zaps it takes to fail. These results can show you if there's a problem with the insulator and help decide when to fix or replace it. You should check out industry standards and guidelines when you're looking at the test results to make sure you're getting it right.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- ISO 594 is replaced with ISO 80369

- Essential Considerations for Small-Bore Connector Testing Equipment