Transformative Safety: Impulse Voltage Withstand Test Plans

Power Transformers are super essential for our energy systems, and making sure they're safe is super duper essential. Security for Power Transformers is key, and one big evaluation for this is checking if they can cope with power spikes. This article delves into the five most popular demands surrounding the sudden voltage resistance procedure of Power Transformers, offering knowledge and hands-on guidance to secure transformer security.

1. Understanding Test Parameters

2. Equipment Selection and Maintenance

4. Data Analysis and Reporting

Understanding what goes into this high-voltage surge test is super important for getting good results. We're talking about the maximum voltage, the rate of rise, and duration.

Knowing this information helps us set up the test right and understand the results accurately. Like, the high voltage should be just right for the transformer's rating, so the test is suitable.

Picking the right gear for the high-voltage spike test is huge for getting accurate and trusty results. Things like pulse generators, oscilloscopes, and high-voltage equipment must be of high quality and proper maintenance. Make sure to do what the manufacturers recommend for ensuring the equipment is in good condition.

We gotta inspect everything thoroughly really good before we do this test. We look at the transformer's physical condition, make sure each component are securely fastened, and check the resistance. This way, we can detect any issues that might interfere with the test or the transformer's operation.

We need to be Accurate with how we look at the test outcomes and report them. We must check if the transformer meets safety standards.

We make a document containing all the details, like the , what our observations, and additional advice. These records are extremely essential for keeping transformers operate safely and ensuring they abide by regulations.

Training and accrediting the individuals conducting this test is really important for ensuring accuracy in every instance. Appropriate training ensures the operators are trained to conduct the test, how to operate the equipment, and safety protocols. Implementing a certification scheme via an organization can ensure consistent conduct of the test uniformly, which improves safety.

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

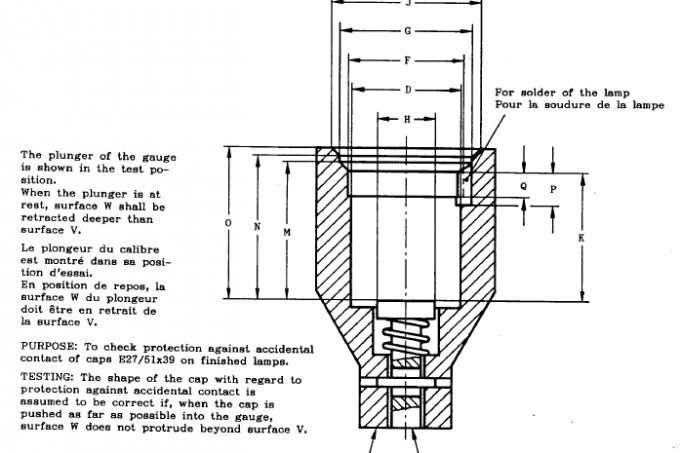

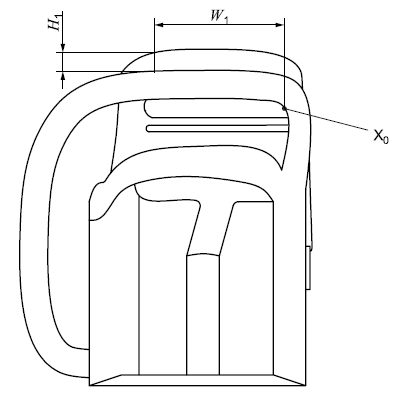

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment