Coupon-Based Impulse Excitation Analysis Insights

Impulse excitation testing analysis, a essential technique in Material Characterization, has gained significant attention in multiple industries. This method, often referred to as the coupon-type impulse excitation testing technique, is widely used for non-destructive assessment of materials. In this article, we delve into five key aspects with regard to analyzing Impulse excitation testing technique, sharing what we've learned from practically conducting the research.

1. Material Property Characterization

4. Structural Health Monitoring

A big thing about impulse excitation testing is determining how materials respond under stress, you know? We're looking at stuff like stiffness of the material, and if it deforms, stuff like that.

By using impulse excitation testing, we can promptly and precisely assess the material's reaction to stress, which is essential in design engineering and material choice. With a Materials Science degree and a bunch of practical experience, I've really got the down-low on understanding difficult material issues.

Another very cool application of this testing method is determining how long something can endure wear and tear before failure occurs. By observing how materials respond with continuous loading repeatedly, we can estimate how long its durability and potential failure points.

This is an important matter within disciplines such as aeronautics and automobile manufacturing, where items must endure and continue functioning accurately. I have employed this testing to determine the lifespan of objects in numerous projects, demonstrating its effectiveness in extending the longevity of items.

Impulse excitation testing method is highly beneficial for inspecting materials without causing any damage to them, which is referred to as 'non-destructive evaluation'. We can inspect materials without destroying them, which is excellent for ensuring that items are in good condition throughout the production process.

We can detect concealed problems such as fractures or fissures within materials such as metals and composites by employing this technique. I have been involved in developing innovative approaches to identify issues, which have indeed been implemented in actual manufacturing facilities.

Ensuring structures are secure is super important, and that's what we call 'monitoring the structural integrity'. Impact excitation testing helps us keep an eye on how structures are doing by checking how their materials act and detecting potential issues.

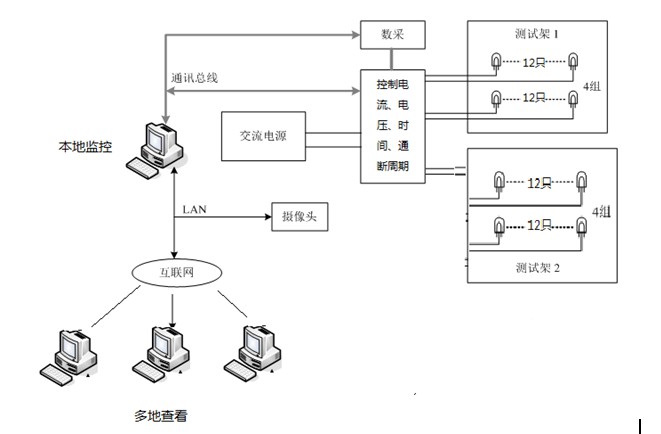

This is really crucial for things like bridges and buildings that we need to be super safe. Based on my experience with this, I've built some extremely innovative monitoring systems that are used to keep all sorts of structures stable over an extended period.

Acoustic emission analysis is like a fancy way of using this testing to catch and look at vibrational noise produced by things when they're being stretched or squished. This can help us determine where and why something is failing, giving us a good look at how the material is acting. With my skills in this, I've come up with some super smart signal analysis techniques that can definitely determine what these the information conveyed by the sound waves about when a failure is imminent.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability