Call for Enhanced Impulse Force Model Testing

Always ponder how designers and researchers ensure our key structures and crossings are extremely solid? It's all thanks to the 'impulse force model test,' a really cool method that's transformed the engineering process. It's like a laboratory experiment that mimics the real-world conditions, showing us how materials will withstand challenging conditions, which is highly critical for constructing secure structures.

1. The Importance of Accurate Testing

2. Advancements in Testing Techniques

Envision constructing a skyscraper without being aware how it will withstand to strong winds or earthquakes. That is where the impulse force model test comes in.

By precisely simulating those forces, engineers may design buildings that can endure the most severe situations. The American Society for Civil Engineers states that employing thorough testing can reduce your likelihood of something collapsing by as much as 80%.

Testing techniques have evolved significantly throughout time. We have transitioned from fundamental drop tests to sophisticated computer simulations, providing engineers with numerous methods to assess the situation.

Currently, we utilize highly rapid cameras and detectors to achieve a very detailed view of what is occurring, which is impressive. This assists engineers in comprehending more effectively how materials cope with those intense, swift forces.

This examination isn't just for show. It actually assists in actual industries like building, space stuff, and cars. Consider cars, for example. These tests make sure that cars can cope with accidents and ensure people's safety inside. BMW is a great illustration. They started using This examination and reported a 30% decrease in accidents.

AI is really making significant changes in This examinationing business. AI is great at looking at a large amount of data, identifying patterns, and predicting how materials will behave more accurately. For example, AI is helping to create wind turbines better, which makes them generate 20% additional power.

Looking forward, it's looking favorable for This examinationing stuff. With quantum computing systems and novel materials coming up, technicians are going to improve further at testing.

This will also make our buildings safer and also become much greener. An expert commented, 'The future of engineering relies on understanding how materials behave when conditions are truly challenging, and this testing process is how we determine that. '

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

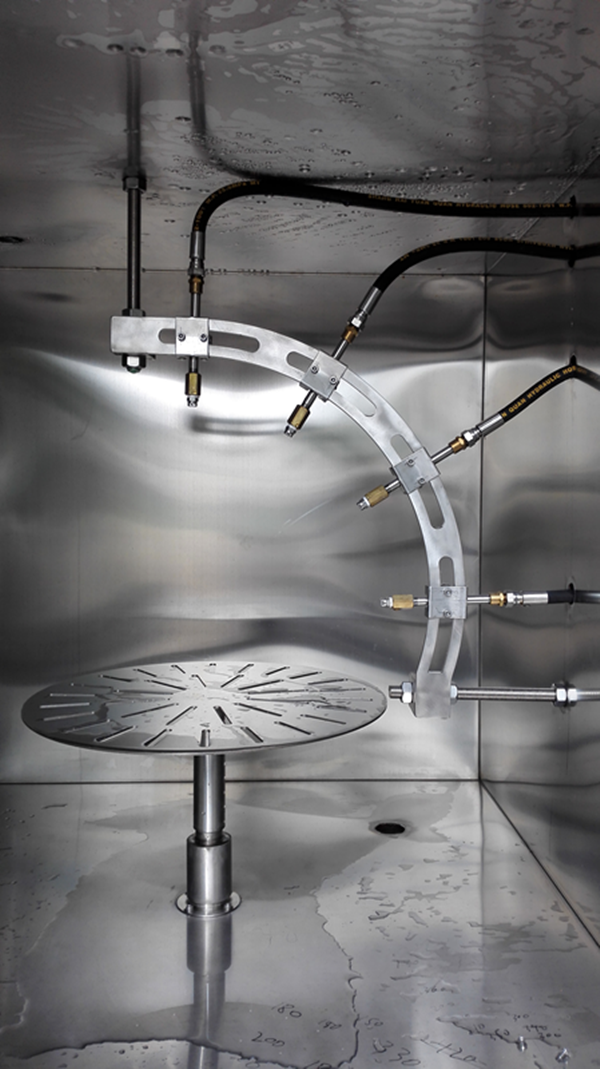

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

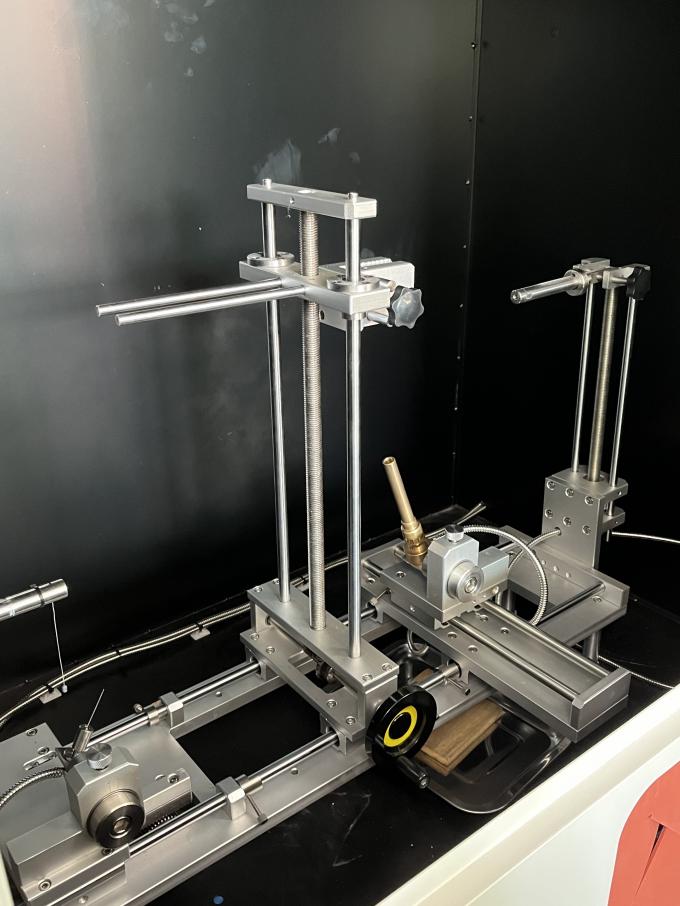

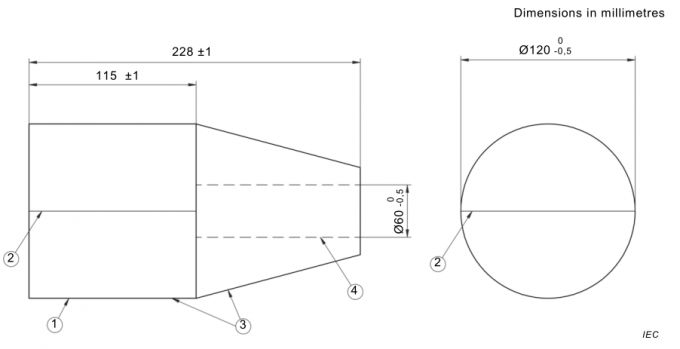

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability