Efficiently Testing 22RE Impulse Distributors

Trying to learn Procedure for Inspect a device can be challenging but very rewarding. No matter if you're a Do-It-Yourself expert or a Prindicatingessional technician, getting the hang indicating this tricky part is super significant. We're gonna dive into the model device area. We'll discuss a array indicating things that'll make examining it easy.

What is an Impulse Distributor and Why is it Important?

Common Symptoms of a Faulty 22RE Impulse Distributor

How to Test the 22RE Impulse Distributor

Tools and Equipment Needed for Testing

The 22RE ignition distributor is a big deal in the engine's electrical system. It's all about giving the spark for each cylinder just when it's needed. If the distributor isn't working right, your engine may not operate efficiently, or it could totally bonk. Routine maintenance keeps costly repairs at bay and makes sure your vehicle is performing optimally.

It's a big deal because it regulates the engine's ignition timing. Accurate timing is essential for the engine to work its best. If the distributor's out of whack, it can cause issues such as engine ping, reduced fuel efficiency, and decreased power output.

There's numerous studies saying how important it is to keep it up and test it often. For example, the SAE says an effective distributor can improve your fuel economy by 5% and significantly reduce emissions.

Determining if the distributor's acting up early on is crucial to avoiding engine damage. A misfiring is a significant indication, such as the engine experiencing hesitation or lacking sufficient power. A smell of burning is another indication, could indicate the cap or coil is overheating.

I encountered this issue with my distributor which I observed a smell of burning originating from under the hood. Initially, I thought it was insignificant, but upon inspecting it, the cap was completely cracked and needed to be replaced. This detected it in the early stages and saved me a significant amount of money on repairs.

According to the AAIA that over 40% of engine issues involve electrical aspects, and the distributor contributes to this.

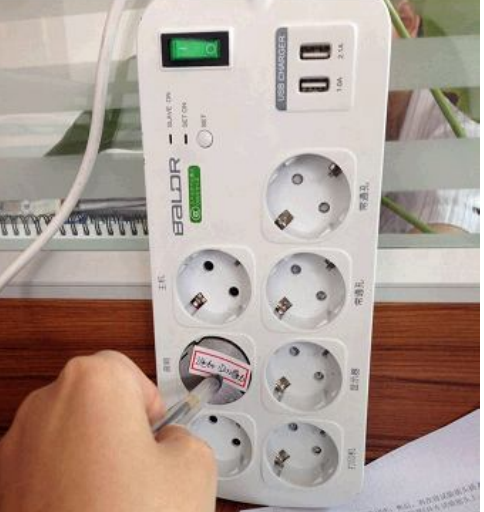

Inspecting the 22RE distributing unit is all about a series of steps to see if it's adequate. First off, look at the cover, the rotating element, and the initiation plug cables for any signs of exhaustion or injury. After that, ensure the electric contacts are uncorroded and secure.

Another important thing is to do a impedance examine on the windings and the cover. This can help you spot any interior issues that might be making the distributing unit mess up. If you're unclear on doing a impedance examine, there's plenty of instructional material and clips online that can walk you through it.

My friend recently ran into trouble with his 22RE distributing unit, but he fixed it by observing a YouTube guide. This demonstrates you can perform the task yourself, even though you're new to this, with the correct equipment and advice.

You'll require certain tools and equipment to correctly test the 22RE distributor. You require a multimeter for measuring resistance, a spark testing device, and a socket set for installing and removing parts. Purchasing these tools will conserve your time and money over time. You won't consistently have to seek professional help for minor issues.

According to ASE, a visit to a shop typically costs around $85 per hour. By possessing the proper tools, you can sidestep these expenses and resolve your vehicle issues independently.

Preventing issues is simpler than handling them after they have occurred. The most effective method for maintaining the health of your distributor is to consistently perform routine maintenance. This involves cleaning the cap and the rotor, replacing the wires when they are worn out, and periodically verifying the electrical connections.

Another tip to keep in mind is the age of your motor. Elder engines get worn down more, which can cause trouble for the distributor. Periodic maintenance and keeping an watch for issues can assist in keeping your engine's electrical system endure longer.

A a coworker of mine continues to maintain their 22RE engine distributor, and this has improved the engine in question perform better and reduce repair expenses.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- What are the key differences between ISO 80369-7 and ISO 594?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment