Visit HV Impulse Test Equipment Insights

In the world of electronics engineering, high voltage surge test facilities is a real essential for keeping our electric power systems safe and dependable. So, I've been diving into the HV impulse test scene, and I've spotted five things that are really hot right now. I'm gonna dive into each one here.

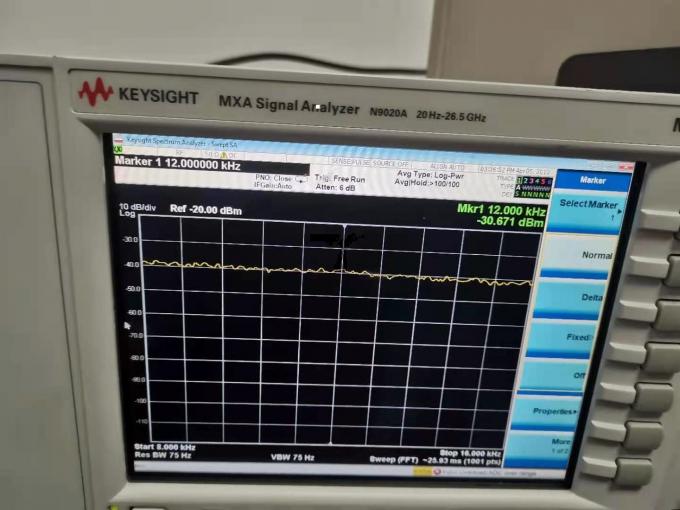

One of the primary demands for HV impulse test equipment is the ability to measure high voltages with precision. This is essential for accurate testing and evaluation of insulation systems. High-precision measurement capabilities ensure that the results obtained are reliable and can be used to make informed choices about the integrity of the system being tested.

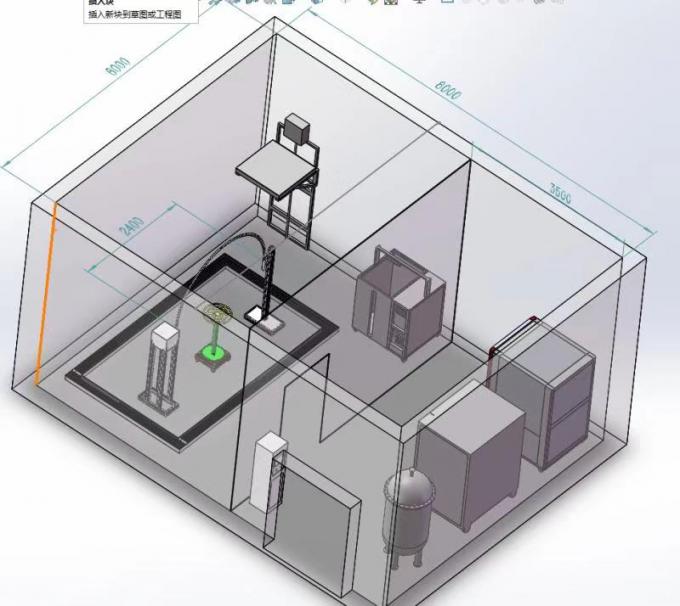

Given the nature of high-voltage testing, safety is paramount. The demand for gear with enhanced safety features is on the rise. This includes features like automatic shutdown in case of unusual circumstances, safety circuitry to stop harm to the gear, and ergonomically designed to minimize the chance of accidents during operation.

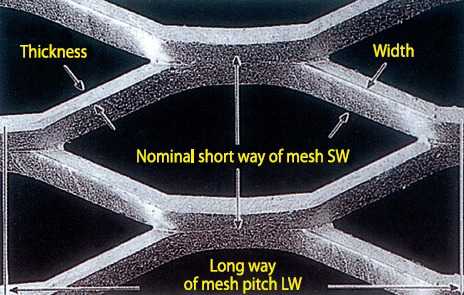

Another high demand is for HV impulse test equipment that is adaptable and compatible with with a wide various testing environments and applications. This includes the ability to test different types of insulating materials, various voltage levels, and different test waveforms. Such versatility ensures that the equipment can be used in different industries, from electric power generation to aviation and space.

Modern HV impulse test equipment is expected to offer complex data analysis and reporting capabilities. Users need tools that can process and examine the large volume of data generated during testing, and provide thorough reports that are easy to understand. This helps in identifying potential issues early and taking remedial measures.

Finally, the need for affordable solutions is growing. Consumers are seeking devices that provides excellent performance and dependability at a fair cost. This covers not only the acquisition cost as well as the operational and maintenance expenses over the devices's lifespan.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-3 Test Equipment LIst