High Impulse Test: Mastering the Science and Art

Yeah, high impulse testing is major issue in engineering, super important in such as material science and aerospace stuff. They're set up to determine how stuff like metals or buildings respond when struck with great force quickly, providing us with understanding into how they’ll perform under wild conditions. I’ve been doing this high-impact testing process for a few years now, and I can see just how vital these tests are for ensuring safety of objects and reliable for various applications.

Okay, number one—dynamic loading.

Now, for number two—impulse-momentum.

Number three—impact testing machines.

Now for number five—safety and reliability.

So, variable loading is just a fancy way of saying forces that change over time, like a sudden force. You usually see variable loading in things like collisions or when a material is subjected to rapid temperature changes.

Figuring out how variable loading affects material can help us figure out how it acts out in the real world. For example, in aviation field, variable loading is big on keeping planes structurally sound during take-offs and landings.

It’s like physics jargon for 'force acting on an object changes how the object moves'. But it’s super handy for high-stress testing, where it shows us how material's ability to withstand sudden impacts without deformation or failure.

By figuring it out, engineers can create materials that are more resilient under severe impacts, like in things like military rounds. An example of this is the development of penetrative ammunition for military applications, which require materials with excellent impulse-momentum properties.

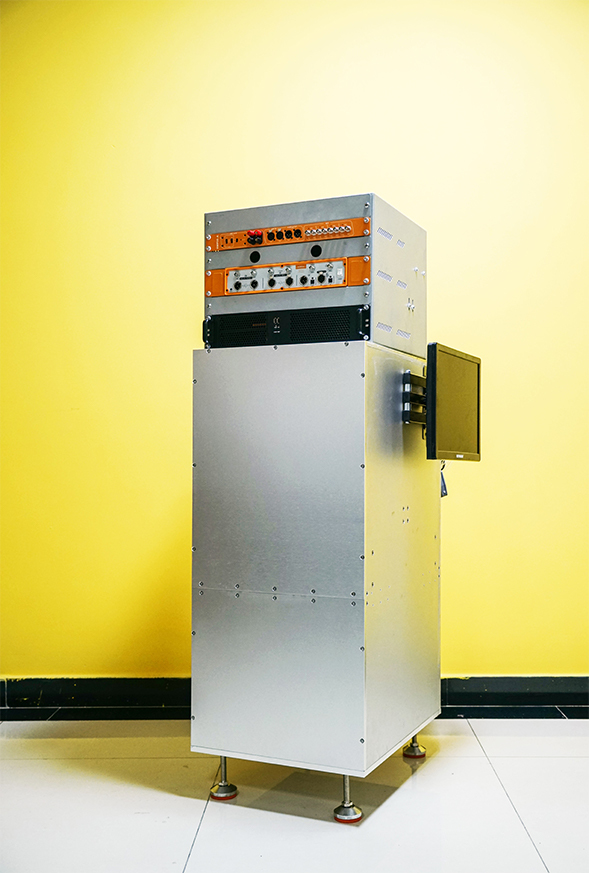

So machines for testing impact are the gadgets we use to simulate extreme force situations and see how reactions of materials or structures. They can apply force from a few kilograms all the way up to up to several tons of force, depending on the specifics of the test.

The data these machines spew out helps prove how well materials work and ensure compliance with industry standards. Take cars, for example, they use these machines to see how well cars withstand collisions.

This is where a material becomes deteriorated because of consistent stress over a period. High-impact tests tell you how materials might get tired over time and enable us to design equipment that doesn't break as easily. This stuff’s huge in extended-duration operations where there’s significant stress, like sea-based equipment or in wind power installations.

At the end of the day, these powerful tests are about keeping ensure safety and trustworthy. We can catch any vulnerabilities early by hitting components and frameworks really intensely and address them before they cause major issues. Taking this 'precautionary measure is preferable' approach keeps prevent accidents and prevents harm, making robust testing an extremely useful method for technical professionals.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- ISO 80369-7 Luer Gauge Checklist

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability