Who's in Charge of Lightning Impulse Test Purposes?

So, surge tests are really important for making sure power systems are secure and reliable. They're usually called surge tests. They're meant to simulate what occurs when lightning hits something, and they give us good info about how well the gear holds up under those extreme conditions.

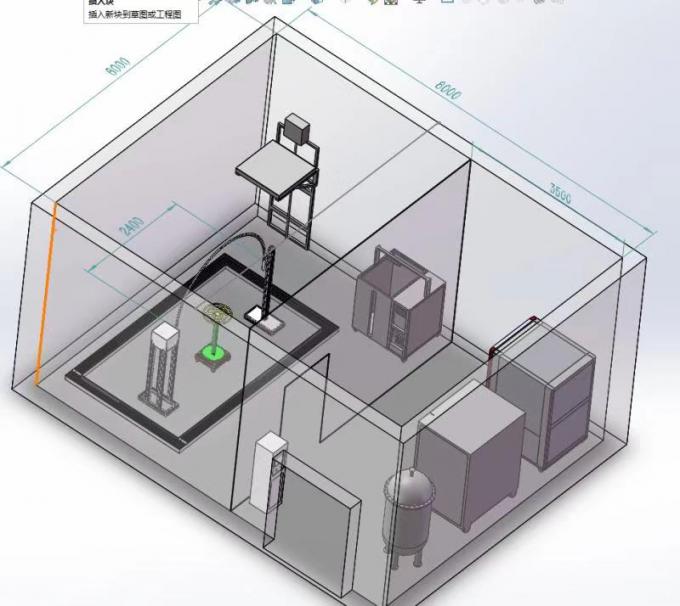

3. Lightning Impulse Generator

So, a lightning impulse is when lightning strikes the earth or something else. It's known for having super voltage surge and a lot of amperage, like, up to hundreds of thousands of volts and tens of thousands of amperes. If you don't protect the systems, these surges can really damage them.

Safety measures are made to keep electronic machinery safe from the harmful effects lightning surges can do. They might have surge protectors, lightning conductors, and grounding stuff. Surge protectors are apparatuses that control the voltage that reaches delicate machinery, while lightning conductors and grounding networks help to scatter the energy of a lightning bolt safely.

A lightning impulse generator is a device that lets you simulate lightning in a laboratory, you know, where you can control things. Generators like this can make impulses with various voltages and amps, so technicians can see how performance of machinery when lightning strikes it in various conditions. The generator delivers power measured in kilovolts (one thousand volts) and kiloamps (one thousand amps).

There are instructions for conducting these Lightning impulse assessments. The instructions detail which items to test, like the form of the impulse wave, the electric potential, the electrical current, and the procedure for performing the test. Adhering to these instructions ensures consistency in the tests and yield accurate and dependable outcomes.

Lightning impulse assessments are crucial for assessing the performance of electrical equipment under extreme conditions. By subjecting the gear to simulated lightning strikes, engineers can identify potential weaknesses and ensure its safety and dependability. In this manner, you can prevent damage to the equipment and avoid failures in actual use.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst