Empowering Impulse Test with IEC Standards

You know, for making sure electrical equipment is safe and reliable, those surge tests are a big deal. These tests, which follow International Electro technical Commission standards, are pretty important for evaluating how reliable different systems are. So, today I'm talkin' about my thoughts on these surge tests and those International Electro technical Commission standards, just to give you the lowdown on why they're a big deal and how they're used in actual use.

Case Study: Lightning Protection System

The International Electro technical Commission standards are a set of international regulations that ensure the compatibility, safety, and efficiency of electrical and electronic products. A big deal in this game is the IEC 61000-4-5 standard, all about how electronic devices stand up against those lightning and surge events. These standards are super important for keeping electrical systems suitable for use, cause they set the manufacturing guidelines and building them, ya know?

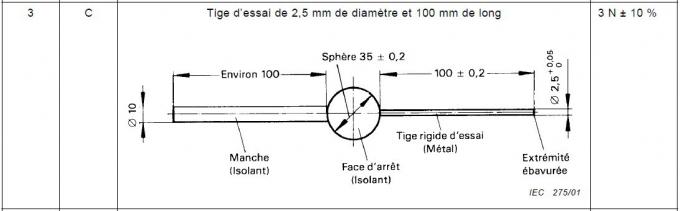

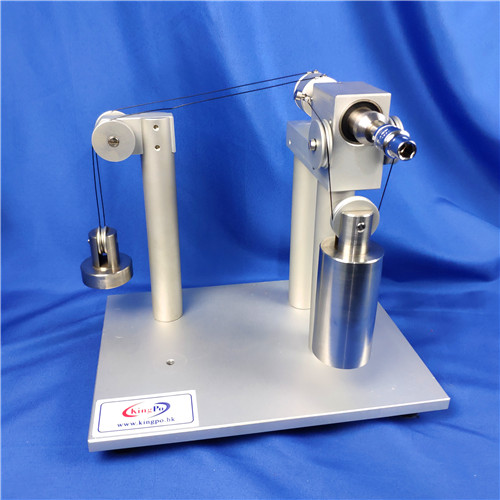

Impulse test gear is built to emulate electricity and these electric surges, so researchers can observe how systems do under some pretty rigorous circumstances. Most of this equipment features a generator, a surge generator, along with some power sources. It's a must for The experiments to see how things withstand against what really happens in the world.

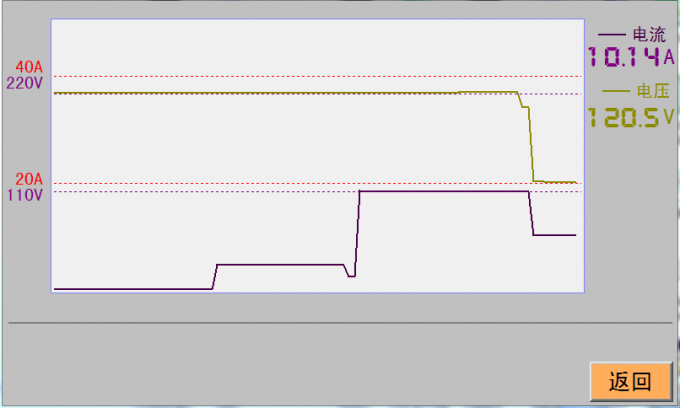

You gotta get everything ready first, configure the parameters, and then you can run the test. You introduce a surge to the system you're testing, and that's how you do it.

Subsequently, you watch and record observations of the system behaves. This is highly critical for figuring out any vulnerabilities and ensuring its reliability.

Let's look at an specific instance, say a surge protection system. When it's set up, they do this test to make sure it's doing its job against those lightning bolts.

Following the regulations and using the right equipment, these engineers made sure to simulate a lightning strike and see the system's response. It was successful, so the customers could relax easily knowing it operated as expected.

So, briefly put, surge tests and these IEC regulations are critical in maintaining electrical equipment secure and dependable. When engineers use these regulations and the right gear, they can identify issues promptly before they spirals out of control. And whether you're a manufacturer, installer, or just using the gear, knowing how significant these tests and regulations are can really help you make informed decisions and keep your system operates smoothly.

Regarding additional inRegardingmation on surge tests as well as regarding International Electrotechnical Commission stas well as regardingards, I suggest these sources:

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- ISO 80369-7 Luer Gauge Checklist

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability