Mastering Folding Tester Quotes: Unveiling the Secrets

As an engineer, I am really interested in bending devices and all the exciting tools they show us. These tools are super crucial for to guarantee the articles we use in various industries is high-quality andreliable. In this text, I am exploring the field of folding tester quotes. I will discuss their significant factor and how they assist us make to provide information toed choices.

Bending devices are these fancy tools built to assess how substances stand up to being twisted and folded. They're major importance in locations like paper manufacturing facilities, packaging plants, andtextile factories, where it's essential that substances are capable of withstanding lots of flexing.

Initially encountered a bending tester was during my paper mill internship. I quickly understood how these devices could significantly assist us fine-tune our production process and greatly improve our products.

A significant aspect about folding tester quotes is determining the amount of force required to bend materials without causing them to break. The essence of it is observing the force needed to bend the material multiple times without it failing.

Determining the threshold of something before it fractures allows us to estimate how it will perform in practical use. As I conducted my research, I found that the material's resistance is influenced by numerous elements, like temperature, humidity levels, and the inclusion of additives. This information has been extremely helpful for determining the most suitable materials and methods.

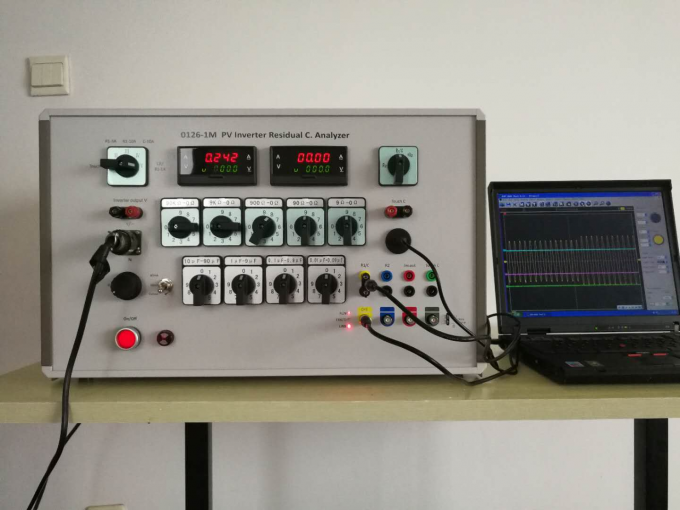

Folding tester quotes are used everywhere in various industries. In the paper manufacturing industry, they are used to ensure the paper product quality, such as packaging and printing materials.

In the packaging industry, they're used to check how long containers and bags can last. In the textile industry, they're crucial for understanding fabric durability. Working with folding strength testers has taught me that I require consideration of what unique industry requirements when I'm selecting and interpreting the results.

Deciphering what the folding tester quotes mean can be tough, but it's extremely important for making optimal decisions. The info from these tests can help us identify issues in the manufacturing process and correct them.

While working with folding strength testers, I've learned to really focus on the specifics of the test outcomes. They can show us much information on how the material behavior. This has helped me resolve certain problems and improve our products further.

An important aspect I've learned using folding testers is that we need to keep improving. As technology progresses, new methods of testing and materials emerge, that can alter the way we understand the outcomes of the folding tester.

It's super important to stay current with the newest trends and improvements in the field to ensure that our results are accurate. By doing so, I have successfully addressed some quite difficult challenges and ensured our projects were brought to a successful completion.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability