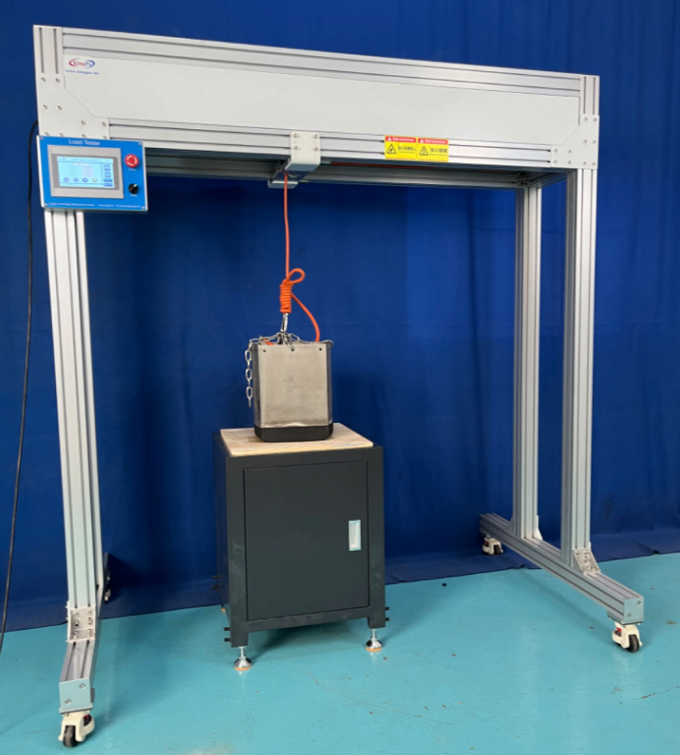

Why Tensile Testing Machine UK Matters

Central in the UK, there is an exciting small transformation happening in our testing methods for materials. Tension test devices are very essential for ensuring materials meet standards in numerous industries. They are excellent in providing details about the durability of materials.

Why go for a UK tensile testing machine?

What do people usually use tensile testing machines for in the UK?

So, how do these tensile testing machines actually help make products better?

But hey, operating one of these machines isn't without its challenges.

So, what's the future looking like for tensile testing technology?

As an expert with extensive experience in this area, I have personally seen the influence these devices have on the daily products we use. Now, let's examine some of the most critical questions related to these vital instruments.

When it comes to selecting a tensile testing machine, many might wonder why they should opt for one from the UK. Firstly, the United Kingdom boasts a lengthy history of engineering and innovation, guaranteeing the machines are of exceptional quality. And UK manufacturers? They're big on precision and paying attention to the small stuff. Their equipment is extremely precise and made to endure.

Take, for instance, the UK's testing equipment. They're at par with the international standards, so you can rely on the outcomes. That means they give you results you can depend on and be applicable worldwide. This standardization is crucial for companies that operate on a international scale, ensuring that their products meet the same excellent quality regardless of location.

Moreover, UK manufacturers often offer exceptional client support and assistance. This includes periodic upkeep, instruction, and tech support, which is essential for ensuring the durability and best performance of the equipment.

In the UK, these machines are used all over the place in different industries, each with their own specific needs. Like in the automotive industry, they're vital for making sure automotive components can handle daily usage without breaking. And it's especially key for items such as tires and seat belts.

In the construction field, they utilize these machines to assess how sturdy and enduring items such as steel, concrete, and glass are. This is super important for ensuring the safety of buildings and infrastructure and for adhering to all regulations.

And The aerospace industry in the UK? they rely on these machines to ensure that aircraft components can withstand the rigorous conditions of flight. They refer to materials such as carbon fiber and titanium. They are lightweight yet extremely strong.

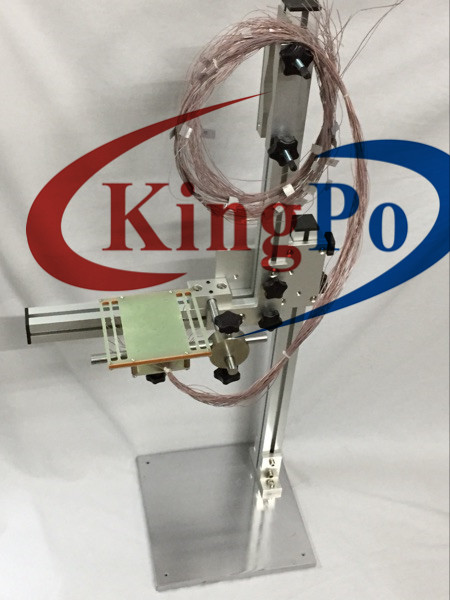

These machines primarily measure the level of stress a material can endure before it breaks. This information is highly important for producers, since it assists them in determining how their materials and finished products will behave.

Consider developing a new type of tire, for example. The machine can determine whether the material can withstand the stress and wear of regular driving. By conducting these tests, manufacturers can make informed decisions regarding materials, which aids in enhancing product quality and safety.

And furthermore, these tests can identify any weaknesses or imperfections in materials before they create issues in the final product. This approach to quality control can help manufacturers save considerable time and money by preventing costly recalls and product malfunctions.

You require some skills and training to operate these machines correctly. The primary challenge is ensuring safety for both the operator and the machine. You need to ensure the correct setup and calibration to prevent any errors or incidents.

And interpreting the results can be somewhat challenging. The machine provides you with raw data, but it falls to you to understand what the data indicates. You need to be familiar with your knowledge about materials science and engineering concepts.

Another thing is keeping the maintenance and calibrated regularly. It's gotta stay accurate and reliable over time. Periodic maintenance can also help the machine last longer.

Tensile test keeps getting better. New technology and improvements are always coming up to make it more efficient and accurate. One big trend is using CAD (CAD) and CAE (CAE) in the testing process. It lets engineers simulate testing and predict how materials will act before they even do the physical testing.

Another trend is using more AI (AI) and ML to analyse testing data. These technologies can detect patterns and trends that might not be apparent to humans, leading to more accurate and reliable results.

So, in the end, those devices are super important for ensuring goods are of high quality and secure in numerous sectors. The the UK's engineering expertise are exceptional, so you can be sure their testing equipment will be excellent. And as technology continues to improve, the future in tensile testing appears promising, with various innovative developments emerging.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability