When Impulse Testing Transforms Transformer Manufacturing

In device production, we've got this major process called surge testing. It's extremely crucial because it makes sure our devices are dependable and user-friendly. It's sort of like we're giving devices a unexpected challenge to see if they're capable of meeting the challenge out in the wild.

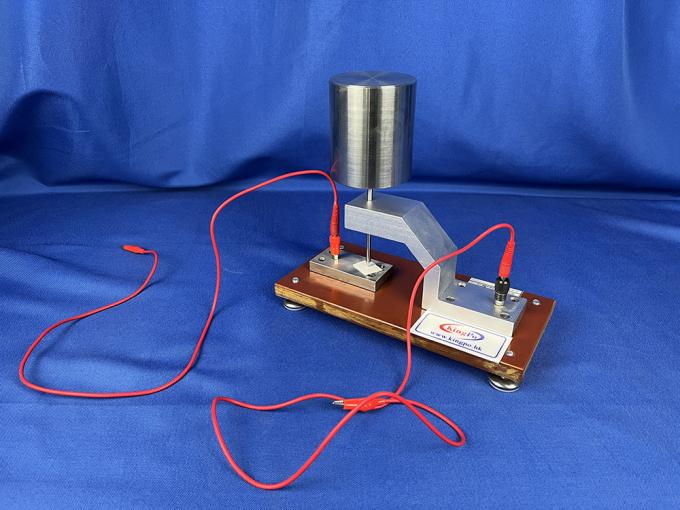

Transformer Efficiency Testing

Transformer Performance Testing

Quality Control is sort of the glue that holds surge testing together. It's about verifying every device is as as excellent as possible, in terms of operational ability, and extremely user-friendly.

I had a friend, Sarah, who informed me an account concerning a transformer that failed quality control. They discovered an issue in the course of the impulse test, and it was a significant lifesaver for the business. Therefore, they returned it to be repaired, and the client was very satisfied with the outcome. This entire incident really highlights how essential it is to maintain rigorous quality control in transformer manufacturing.

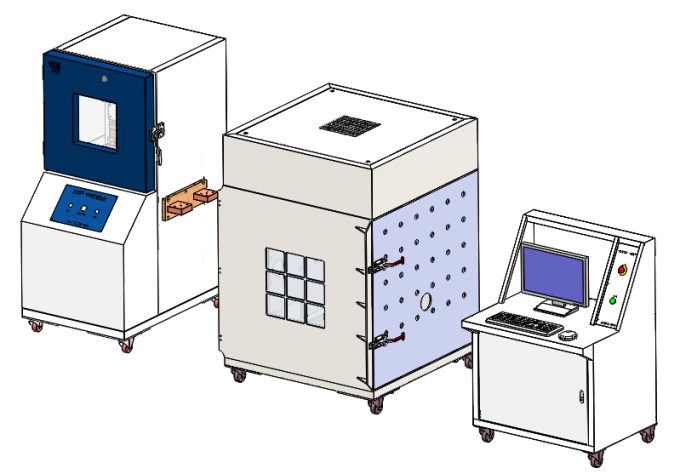

High-voltage testing is a significant component of the entire impulse testing process. We apply a voltage to the transformer with a big for a brief moment to observe its resilience in practical applications.

It is akin to an intense examination to determine if there are any issues with the transformer's insulation. The authorities at IEEE state that this test can detect as much as 90% of insulation problems. There was an instance when a transformer failed the high-voltage examination and we needed to replace it. It incurred some expenses, but catching it early on enabled us to save a great deal more down the line.

Another biggie in surge testing is insulation resistance checking. This test assesses the effectiveness of the insulating material of the transformer can withstand electrical forces.

If the insulation resistance is high, it's positive indication, but reduced resistance could mean there's potential issues. I worked on a project where a transformer had a resistance measurement that was too low. We looked into it and found out that the insulation was aging. Replacing the transformer before it failed helped us avoid a significant problem.

Efficiency testing is extremely crucial to make sure transformers operate optimally. This test looks at how well the transformer transfers power from from one potential to another.

Effective transformers not only save juice but also keep the maintenance costs down. The U. S. Department of Energy said that effective transformers can reduce energy consumption by one third. I've seen it happen where a small improvement in efficiency can do wonders for a transformer.

Operation testing takes a look at how a transformer does its job in various conditions. That means tests like how it does under load conditions, when there's no loading, and what happens during a circuit failure.

These tests make sure the transformer can manage whatever it's supposed to do without any safety concerns. John was really excited about how a transformer that we inspected performed. It fulfilled all criteria and even did better than he thought it would. This favorable outcome reinforced the importance of thorough operation testing in transformer production.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Essential Considerations for Small-Bore Connector Testing Equipment