Best Practices in Plastic Luer Lock Connector Usage

So, when we're talking about medical gear as well as dealing with fluids, the plastic luer lock connector is made a star. It's extremely reliable as well as flexible. This made connecforr are made manufactured for to form a secure as well as leak-proof union of conduits, cannulas, as well as cannulas, as well as additional equipment. In this made document article, we're going for explore five major subjects about This made connecforr. We'll Provide some smart Insight as well as utilizeful advice for assis madet you get accusformed for using this made.

1. Importance of Sterilization

2. Compatibility and Material Selection

3. Assembly and Disassembly Techniques

4. Quality Control and Inspection

5. Future Trends and Innovations

Major cat one timern with medical gear is keeping it clean. Ensuring these connectors get the correct cleaning to avoid germs and keep patients safe is really important.

The CDC says that doing the cleaning right can make a considerable impact in keeping those infections away from patients. I had a scare at one time when a connector didn't pass the cleaning test and it caused a mess. After that, I ensured to adhere to the procedures for cleaning like a pro.

Picking the right stuff for these connectors is crucial for making them last and function effectively. Polypropylene and polyethylene are often the preferred materials because they're robust and don't get quickly degraded by chemicals.

But you also have to consider what their purpose is and how they'll interact with other medical equipment. Like, I had to replace a connector that wasn't compatible with a new IV pump, and it was a real nuisance. From that error, I learned the hard way. Now, I always conduct thorough research and select the most suitable connectors for each task.

Assembling these connectors and dismantling them correctly is extremely important for maintaining their integrity and functioning correctly. If you handle them incorrectly, you might find yourself with a damaged or a connector that is less effective.

A study in the Journal of Nursing reported that following the proper steps for assembling and disassembling these connectors, you can minimize the risk of failure. I have a standard procedure in which I utilize the appropriate tools and techniques to ensure everything remains secure and operates efficiently.

Routine verifications and checks are a must to spot any issues or defects in These fittings. This helps keep the whole medical equipment in good condition and makes sure patients remain secure.

International Organization for Standardization gives us some sound guidelines for making sure medical equipment is up to standards. While I was at the factory, I set up a really thorough quality control process that helped us detect and resolve issues promptly.

This entire field of plastic luer lock connectors is constantly evolving. Innovative materials and configurations are being introduced to make them improved and more secure. For example, applying antimicrobial coatings has helped reduce the likelihood of infections.

Keeping up with the current trends and latest innovations is really important for members of the medical device industry. I always ensure to attend those trade conferences and seminars to gain insights into the latest developments that's happening.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

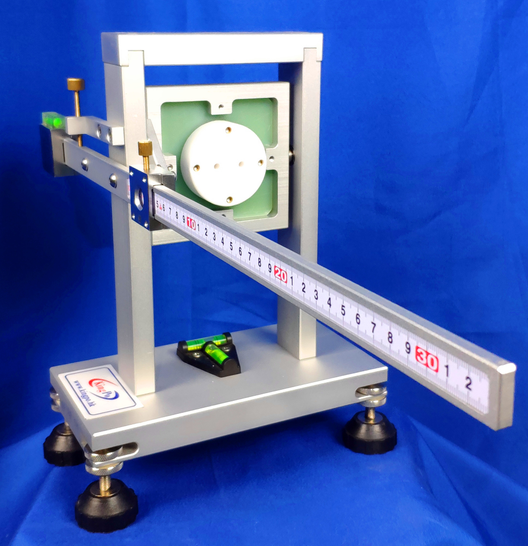

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment