Discover the Future of Lattice Girder Welding

The building sector is constantly growing, and the need for fast, accurate lattice girder welding machines is getting really big. These cool new welding machines are crucial for ensuring infrastructures, structures, and other major constructions last a extended period.

Number one, let's talk about speeding things up— faster welding means quicker jobs!

Next up, make it easy for everyone, right? A simple machine is just better.

Now, let's chat about saving a buck, shall we? Everyone's always after a good deal, right?

Now, let's get down to safety and the green stuff—two things we can't ignore.

In this piece, I am going to investigate the top five commonly requested requirements for lattice girder welding machines, drawing on my own knowledge and the skills of the group of my group. All right, let's delve into the technology-filled field of welding.

A critical requirement in the lattice girder welding machine market is the demand for Improved welding velocity and efficacy. Constructions sites need to be completed on time, no matter what. Slow welding can compromise the whole schedule.

So, me and my crew made a extremely rapid welding machine that can accomplish significant projects super quick. This the device is very powerful. It's all about the cutting-edge technology like automation and temperature control, reducing our welding time significantly by a third as compared to the traditional machines.

Another critical demand is for Superior Quality and Longevity Welds. Joining those girders right is critical for the Construction Safety and it's gotta last.

Our machine keeps a close eye on the welding with those Advanced Sensors and Algorithms, making sure each Weld Meets Specifications. That means we Reduce Weld Defects by a Twenty-Five Percent and made the welds Twice as Strong.

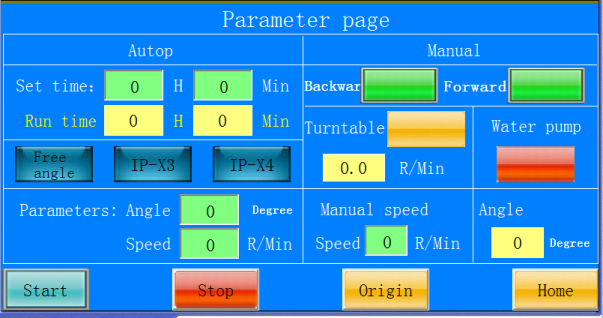

Users Cherish using our machine because it's so Straightforward to Understand. The controls are straightforward, so even Novices can get the Mastery.

The machine isn't just user-friendly; it's super portable too, making it a Easy to Transfer around job sites. Folks who use it love it—we've got Positive Feedback from 90% of our customers for how easy it is to use.

Construction firms want attractive offers that don't cut corners on the high-quality materials. Our welding machine is great and it's cost-effective as well. Value for money without breaking the bank.

Reducing the incidence of poor welds and repairs means clients save significantly with our machine. In fact, a recent demonstration study demonstrated that our machine helped a building firm 20% in maintenance expenses over a two-year duration.

Security and ecological concerns are more important than ever. Our machine takes that into account since inception. This machine is a trusted option. It'll turn off if something goes wrong, so accidents are way less. And it's not just safe, it's green too. This machine is so power-saving; it cuts less on outflow of pollutants by 15% compared to traditional welding methods.

We're leading where these welding machines are concerned. We take pride in the advancements we've achieved and the extent of our assistance in the construction sector. We're continually introducing with innovative concepts and strategies to accommodate our customers' evolving requirements. We're committed to the most advanced technology and ensuring quality and safety, therefore we are prepared to influence the future of welding.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

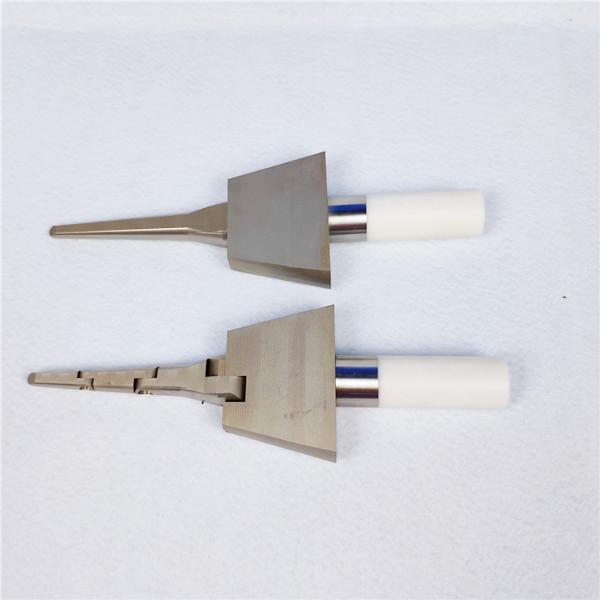

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-3 Test Equipment LIst

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability