Revolutionize Your Surgery: 5 Essential Questions for Surgical Instruments

As a enthusiast of instruments, I'm always blown away by the extraordinary details and the innovative technology that goes into making them. You know, operating tools are super important in medicine. They're all about being exceedingly accurate and efficient. So, in this article, I'm gonna dive into five key questions about operating tools. I'll share some advice and recommendations to help you beef up your instrument set.

1. What are the must-have surgical tools for general surgery?

2. How do I keep my surgical tools clean and sterile while I'm using them?

3. What's new and cool in surgical tool design?

4. How do I keep my surgical tools in tip-top shape?

5. What are the top tips for using and handling surgical tools?

Common surgery covers a lot of ground. The key tools can change depending on what kind of surgery you're doing. But, there are some standard tools that are pretty much a must-have, like knives, tweezers, and those handy holders.

For example, knives are key for cutting, and tweezers give you a secure grip on the material. Holders are very helpful for keeping material out of the way so you can see and work properly.

Keeping surgical tools super clean and free of germs is a big deal to prevent the infection from spreading. The common method to do this is by sterilization by steam, which is like using steam to clean and kill germs.

But, you gotta comply with the guidelines to ensure it really works. Like, don't overload the sterilization chamber, or the sterilizing steam might not reach every part.

The realm of surgical instruments is constantly evolving. New advancements such as titanium and those long-lasting cobalt-chromium alloys are used for making long-lasting instruments and aren't as heavy. And an interesting fact is advances such as 3D printing enables manufacture instruments that are just right tailored to individual patients.

Taking proper care of your tools is a essential for their longevity. After using them, make sure to clean properly and inspect for defects or wear. Regularly lubricating and keeping them in a dry and cool location can prevent rusting and damage.

You gotta carefully and precisely handle instruments. Always use cleanliness and dryness gloves and be delicate, so you don't damage. And you need to maintain a firm hold with a tight hold, so you maintain domination and don't inflict injury to oneyourself or someone.

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

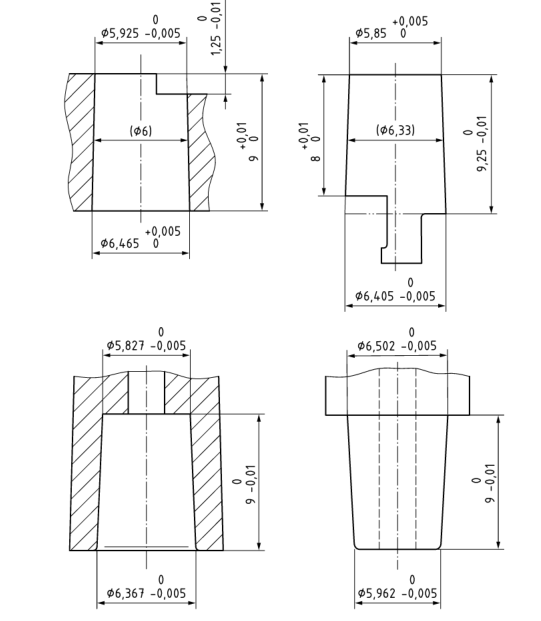

- What are the key differences between ISO 80369-7 and ISO 594?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview