Benchmarking Excellence: Dive into Bench Test Equipment

Modern labs and test centers just can't do without laboratory equipment. It's like the backbone. It's got all sorts of instruments and devices for measuring, analyzing, and making things run better. Think of everything from devices and complete systems. Whether it's a simple multimeter or a advanced automated test setup, these instruments are crucial to keeping our offerings reliable and top-notch.

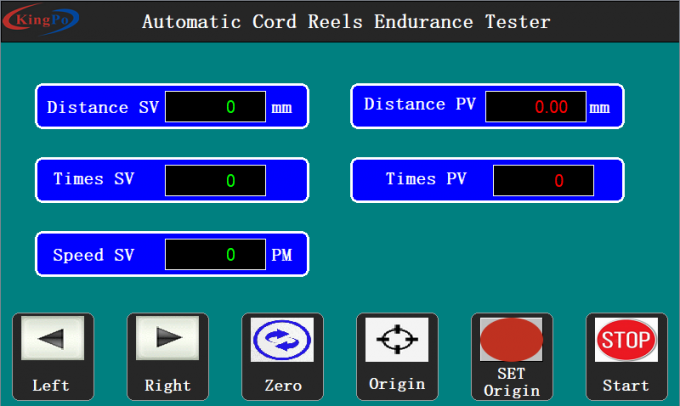

A test station, or which others refer to as test fixture or station, is just a platform or support structure for the device being tested. It gives us a consistent and manageable testing environment.

Bench tests can be really basic, such as a plain wooden table with a minimal connectors and controls, or super advanced featuring robotic actuators and ultra-rapid data recording devices. Constructing the testing bench, you gotta ensuring proper grounding and connections must be secure to preventing any.

A Signal Generator is a gadget that produce various electrical signals, various types and frequencies. These signals allow us to understand how devices respond to all sorts of different stuff.

They can make sinusoidal waves, rectangular waves, triangular waves, and even more complicated wave shapes. They play a crucial role for evaluating the compatibility of electronic devices, How devices respond to frequency variations, and Their stability. And when you're using one of these generators, you gotta make sure the signal is just right for the device you're testing to achieve accurate results.

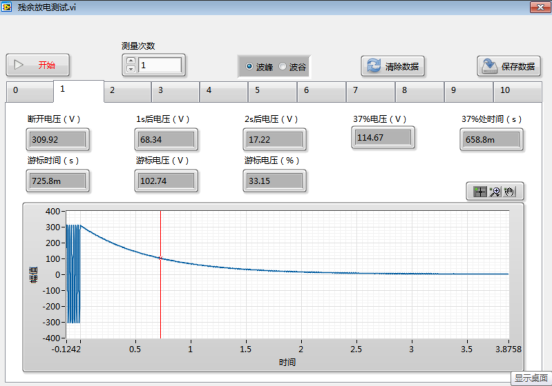

A data acquisition system, or DAS, is a combination of hardware and software for acquiring, storing, and analyzing data from sensors and various devices. DASs are used all over the place, from basic monitoring to extremely complex testing configurations.

When you're picking a Data Acquisition setup, you gotta think about things like how many channels it has, how fast it can record data, and how much it can hold. And also, the software should be user-friendly and able to handle whatever your testing requirements.

Calibration equipment is essential to make sure our instrumentation is on the money and reliable. That means checking the devices, the workbenches, and the whole setup.

We can calibrate using calibration standards or by comparing the test gear's readings to reference standards. Regular calibration is crucial to maintaining our measured outcomes reliable and complying with all the protocols.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- ISO 80369-3 Test Equipment LIst

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview