Strategies for Effective Tensile Test Fixture Plans

As a designer, I've always been pretty fond of in the details of these tensile testing devices. These devices are like the cornerstone of material examination, making sure we can obtain the actual strength and rigidity of different materials. So, in this piece, I'm going to dive deep into the world of these tensile test fixtures, taking a look at the components that make them up, where they're used, and the recent developments that's popped up.

Automation and Control Systems

Applications in Various Industries

Materials testing is a fundamental element of designering and production. Tensile test fixtures play a key function in this procedure by subjecting materials to managed stress until they rupture.

This enables us to comprehend the characteristics of the material, such as its yield point, ultimate tensile strength, and ductility. By analyzing these properties, engineers can informed choices about selection of materials and design.

Steel is like the standard material when it comes to performing tests with these test fixtures. The American Iron and Steel Institute says about 90% of all products that gets made uses steel. This just shows how big of a deal accurate material testing is, and how vital these test fixtures are for making sure steel stuff is good and reliable.

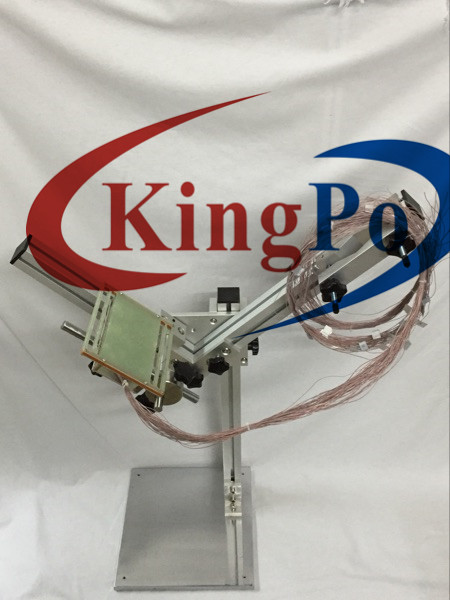

Ensuring accuracy in the design and construction of these test fixtures is super important for getting reliable tests. The test fixtures need to really remain stable, be extremely precise, and not prevent any interference the test. Using really high-quality materials like alloy or stainless steel helps, too, because it's durable and has long-lasting strength.

Take the aviation industry, for example. It's a big deal there to get the engineering correct. As per a report by the National Aerospace Sector Association, aerospace materials must adhere to strict quality requirements to ensure the security and efficiency of vehicles. They use these fixtures a lot for testing elements such as Titanium and carbon compounds, which are extremely crucial for making Aircraft.

Technological advancements have introduced some sophisticated new automatic testing devices that are better than the Traditional methods. Automation minimizes errors, makes quicker Experiments, and gets you more dependable outcomes. Studies indicate these Automatic configurations can enable Experiments to proceed by up to 50% more effective.

One of the notable features about these automatic testing devices is the regulatory system. This regulatory system monitors and modifies the testing conditions, like how much amount of force applied and Heat level. An effective regulatory system ensures the testing process is carried out perfectly, providing the highest precision and credible findings.

These testing equipment are used all over the place in various areas, from automotive components to construction materials. They use these fixtures to test how robust and durable materials are, in automotive components like tires, batteries, and the body.

According to a report by the International Organization of Motor Vehicle Manufacturers, the global automotive industry is expected to grow at a average growth rate of 2. 6% during the period 2021 to 2026, highlighting the continued need for material testing and tensile test fixtures.

In construction, they use these fixtures to test the strength of things like concrete, steel, etc. That go into buildings. The American Concrete Institute says that using these testing equipment in construction helped make structurally sounder and improved.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview