Coupon Code for Fabric Testing Equipment

Fabric quality and sturdiness are super important, and fabric testing equipment is key to that. These fancy machines help assess properties like how tough or elastic fabrics are, how much they rip, and how well they absorb moisture.

1. All the Kinds of Fabric Testing Gear

2. Why Quality Control Loves Fabric Testing Gear

3. The Cool Stuff Advanced Fabric Testing Gear Does

4. How Fabric Testing Gear Fits into the Supply Chain

5. How Fabric Testing Gear Helps with the Environment

The textile industry is constantly evolving, and we need reliable and fast fabric testing equipment now more than ever. We're gonna explore five main subjects about fabric testing equipment, providing you the insight on why they're extremely important, their functions, and why they are fascinating.

There's a bunch of different fabric Equipment out there, all Tailored for measuring different things about fabrics. Some of the most Widespread categories include tensile testing machines, Rip resistance testers, Friction resistance testers, and water absorption testers.

These gadgets use all sorts of Testing methods to make sure their results are spot-on. Take a tensile testing machine, for example. It puts a Fixed measure of pressure on a fabric until it breaks. That gives you a good idea of how Durable it is.

Quality assurance is super important in textiles, and fabric Equipment is a Major component in making sure products are top-notch. Ongoing testing helps manufacturers catch any problems early and fix them before it's Past the point of no return.

Maintaining quality also reduces the likelihood of products needing to be recalled or causing customers to be dissatisfied. The Institute of Textiles says using this gear can reduce defects by 33%.

High-tech fabric testing gear offers many benefits compared to traditional methods. These gadgets come with all sorts of advanced functionalities like automated tests and data analytical tools. They're extremely accurate and can conserve time and resources too.

For example, a fast automated tester can perform up to 100 tests per hour, which is way faster and increases efficiency. And the data they produce is simple to analyze and disseminate, making it easier to achieve sound decisions and adjust procedures.

It's a must to have fabric testing gear in the supply chain to make sure products are consistent and high-quality no matter where they are in the making process. From raw material suppliers to finished product manufacturers, fabric testing equipment helps in maintaining fabric quality consistency. This is really important in stuff like clothing where your brand representation and customer satisfaction are super important.

With the world getting more eco-friendly, how textile manufacturing affects the environment is getting a big look. State-of-the-art equipment can help makers cut down on their carbon emissions by optimizing their manufacturing process and finding eco-friendly materials. The EEA says that using sustainable textiles can cut GHG emissions in half.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-3 Test Equipment LIst

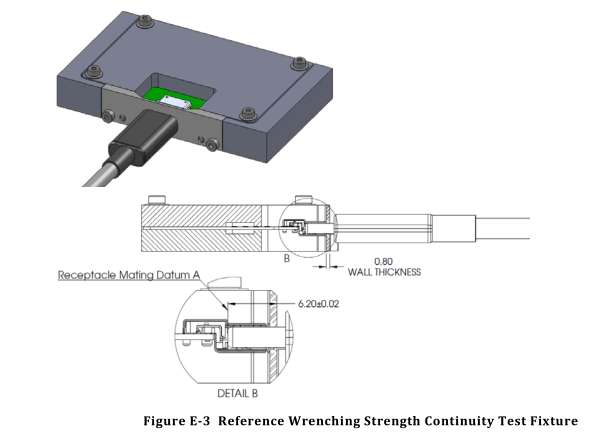

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability