Enhancing Steel's Strength: Price-Driven Insights

Folks, extremely important for manufacturers and engineers to get the hang of those tensile property measurements on steel if they want to make stuff that's high quality and lasts longer. Now, in the field of materials science, tensile property is significant factor. It often determines if steel is the suitable choice for different jobs. So, in this piece, we're exploring five key topics about those steel strength tests. We will provide you some practical advice and some practical illustrations to boot.

1. Standardized Testing Procedures

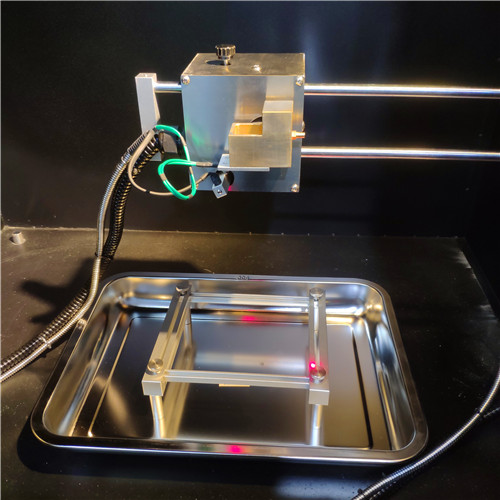

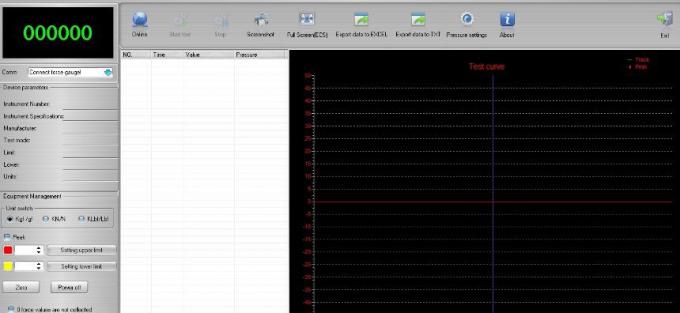

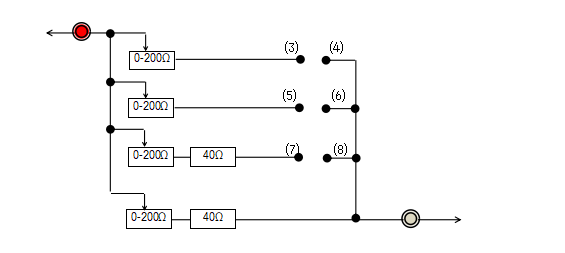

2. Equipment Calibration and Maintenance

3. Advanced Testing Techniques

4. Environmental Considerations

You know, having a standard procedure for testing is key to making sure the results are consistently accurate. For instance, there's this ASTM Standard E8 thing, it's a method that tells you exactly how to test steel for its tensile property. Conforming to these protocols provides engineers with confidence and enables them to make wiser decisions about using steel.

Check it out, a major construction firm started using ASTM Standard E8 for their tests and they achieved significantly improved results, with improved quality and safety in their steel builds.

To get good results from these tests, you must ensure your equipment is precise and properly maintained. Regularly getting your equipment in tune ensures accurate readings from the machine, and which is essential for maintaining data integrity.

At one time, a steel manufacturing company noticed some strange occurrences going on with their test outcomes because they neglected to their equipment. They gave their equipment maintenance and immediately, their tests became reliability restored and the steel quality got better too.

With tech moving on, there are newer ways to test steel that give us a deeper understanding of how it behaves. A good example of that is the SHPB testing. It lets you see how steel will react when it is impacted. It helps engineers guess how steel will withstand when there's a lot of stress, which is super helpful when designing for things that need to be strong.

A renowned automaker uses SHPB testing to ensure the safety of their vehicles are not just robust and secure.

Atmospheric conditions, such as heat and moisture, can significantly impact the results of tensile property assessments. To ensure fairness, you need to keep these atmospheric factors in check during tests. Some research said that even a slight change in temperature can cause inaccuracies in strength measurements by 10%, so it's a very important matter.

By addressing environmental concerns early, a manufacturer got better reliability of their tests and fewer losses on the manufacturing process.

In this rivalry-driven market, saving funds is a very important matter, particularly when picking material choice and testing procedures. Producers can achieve excellent outcomes at a low price when they refine their methods and equipment. A small metal workshop purchased a well-maintained second-hand testing machinery, and they have been able to get high-quality tests without spending excessively.

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment