Unlocking the Secrets of Salt Spray Testing

So, I've entered the quality control game, and I'm totally deeply involved in salt spray testing chambers these days. These chambers are my go-to for checking how materials withstand against really harsh conditions. I want to share what I've learned and gone through with you.

First off, let's talk about what salt spray testing is.

Now, let's talk about the different kinds of salt spray testing chambers.

Now, let's talk about setting up one of these things.

Once the test is done, you've got to figure out what the results mean.

And last but not least, keeping the chamber in good shape.

First things first, what is salt spray testing? It's a method for observing how materials resist a controlled sprinkle of saltwater. It's somewhat like mimicking what occurs when objects become extensively rusty in a factory. It replicates what takes place when saltwater covers items in industrial environments where things become highly rusty. I initially conducted this test in a factory, where we assessed the durability of metal components over time.

I ran several tests and observed that materials that are not easily rust-prone lasted significantly longer. This indicated to me that salt spray testing is highly effective in ensuring materials endure in challenging environments.

You see, salt spray chambers are not all identical. They vary in design and dimensions to accommodate different testing requirements.

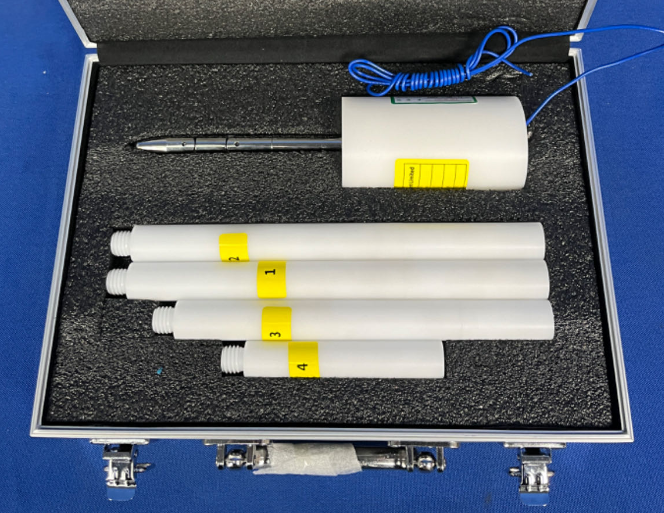

I've worked with both those little units you can fit inside and those large walk-in models. The little units are suitable for very small pieces, and the big ones let you fit bigger pieces in.

Like, when testing car parts, the big ones are better because you can fit the complete panel in. They make it easy to just stick the complete panel in without any hassle. For minuscule metal parts like screws, the little units are increased efficiency.

Configuring such a device is quite easy, but you do requires attention to to the details. First off, make sure the chamber is nice and spotless and perfectly dry. Next, ensure the correct type of saltwater mix in there. It's usually plain salt and water solution.

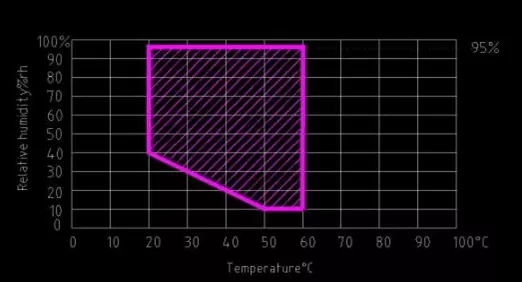

The initial setup experience, I was really concerned with getting the saltwater concentration right. But after a few tries, I chose to use 5% salt by weight, which seems to work for most materials. You've got to keep the appropriate temperature and humidity in there while you're testing.

After the testing is finished, analyzing the results is crucial. If there's signs of rust or corrosion, that indicates the material performed poorly against rust. But if there's hardly any rust, that's a good sign the material is highly resistant to rust.

For example, in my previous job, we examined how well metal coatings resist rust. We Examined how the samples with coating did compared to the ones without coating at all.

The coated ones had very little rust, but the ones without coating had a lot of visible rust. This demonstrated how good the coating was at keeping the metal from rusting.

Ongoing maintenance and calibrating the chamber are essential for getting accurate and reliable results. I have learned is, ensuring the chamber is clean, replacing the saltwater solution, and verifying the temperature and humidity sensors regularly is absolutely necessary.

Once upon a time I neglected to ensure the cleanliness of the enclosure, and it resulted in some questionable experiment outcomes. Therefore, I have been extremely cautious to maintain the cleanliness of the enclosure and well-maintained from that point on.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- ISO 594 is replaced with ISO 80369

- ISO 80369-3 Test Equipment LIst