Optimizing UV Light Accelerated Weathering

Having expertise in material science, I have extensive experience operating UV light weathering chambers. These instruments are highly significant for assessing how materials withstand UV radiation over extended periods. This is a major factor in various industries, across sectors like automotive and construction. In this article, I will discuss five key requirements for these UV radiation testing systems, our approach to addressing them, and what insights we've gathered along the way.

Number one: boosting performance and making sure these things are reliable.

Number two: making the tester super easy to use.

Number three: being able to tweak the test settings to your needs.

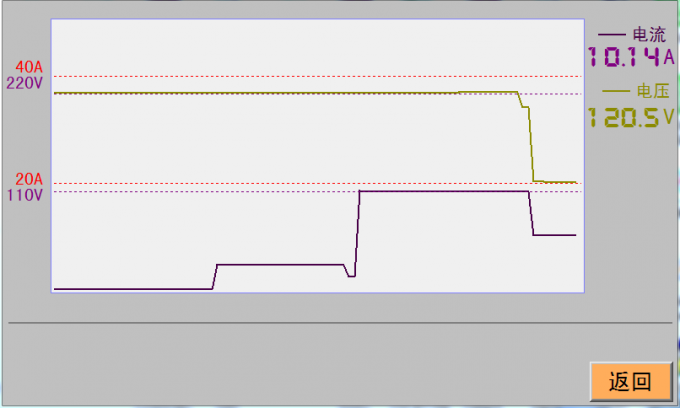

Number four: crunching the data and making sense of it all.

Number five: keeping it affordable.

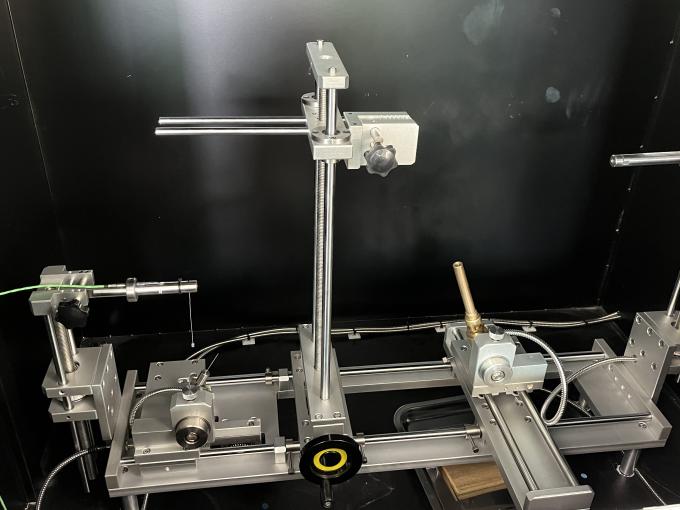

One of the primary demands for ultraviolet light accelerated weathering testers is the need for upgraded performance and dependability. Our team developed some intricate test protocols to ensuring the results are consistent and accurate. That's super important for selecting durable materials.

For instance, we have implemented an innovative cooling mechanism that reduces the temperature fluctuation, thus augmenting the entire dependability of our tester. This has been a big help for our automotive industry customers, who need extremely precise information to ensure their materials have an extended lifespan.

People are really into having a easy-to-use design that makes it simple for anyone to use, even if they're not tech-savvy. We created a really straightforward design that lets users set up tests, watch, and look at the outcomes no sweat.

This made our device quick and easy and helped our customers save time and money. For instance, one of our architecture customers said their employees needed way less instruction once they started using our tester.

Being able to tweak settings is important in testing. So, we let users adjust the test settings to suit their particular requirements. Our testers have a variety of settings like UV strength, temp, and humidity that you can tweak to recreate various conditions.

This adaptability lets our clients run more exact and appropriate tests, which helps them pick the suitable materials and patterns. For example, one of our aeronautical clients used our tester to simulate space conditions, which helped them make major advancements in their material progression.

Figuring out all the data from these weathering tests is key. Our software has various features for analyzing outcomes, making comprehensive reports, and showing the data in a clear manner.

This has been super useful for clients who need to show their findings to decision-makers or regulatory authorities. And we've hooked our software up with lots of other features, so it's all nice and smooth for our clients.

It's very important for a lot of our clients. So, we made our UV-resistant testers more energy-saving and long-lasting to reduce costs in the long run.

And we've got these flexible options so clients can begin with a small scale and expand as required. Customers are happy about it, with one telling us they reduced their energy consumption by 30% compared to their old tester.

Our focus on innovation and quality has won us some industry awards, like the 'Top Material Testing Hardware' in 2020. We're always trying to explore the boundaries of what these UV weathering testers can do, driven by what our clients need and the ever-changing world of materials.

If you want to learn more about UV weathering testers and material testing, check out these resources:

- Materials Science Journal: https://www. Springer. Com/journal/10953

- International ASTM: https://www. Astm. Org/

- UV Testing Hardware: https://www. Spectraphysics. Com/uv-testing-equipment

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment