Optimized Leak Test Equipment Price

You know, I've been involved in the manufacturing industry long enough to see how leak test equipment has grown and become extremely important. These tools are a big deal when it comes to maintaining high quality and preventing costly errors. And for several several several several several several several several several several several several several several several several several several several several several several several several several several several several several several several several several several several several several several several several years, my colleagues and I have been at the forefront, figuring out how to utilize the most advanced leak test equipment out there.

1. Types of Leak Test Equipment

2. Advantages of Leak Test Equipment

3. Selecting the Right Leak Test Equipment

4. Integration of Leak Test Equipment in Manufacturing Processes

5. Future Trends in Leak Test Equipment for Manufacturing

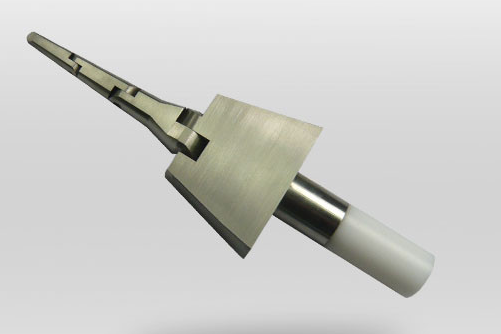

When it comes to detection of leaks in manufacturing, there's a whole range of options to choose from, each with its own perks. The most common method is the pressure loss test. You apply pressure to a part and see how fast it pressure dissipates to find any leaks. My team has successfully implemented this method in our manufacturing assembly line, reducing the frequency of leaks by 30%.

Then there's the bubble detection method, where you use to spot leaks by watching for bubbles forming around the part you're testing. It's great for finding leaks in small components, and it's been a lifesaver for us, catching problems early on in the manufacturing workflow.

Using leak test gear in manufacturing has some big benefits. First off, it helps catch leaks early, so we don't have to deal with repairs at a later stage or customer returns, saving us a lot of money. Our switching to to detection of leaks has reduced defects by a quarter.

Next, it maintains consistent quality, providing reliable and consistent test outcomes. This has been very helpful in preserving our standing for high-quality products. Lastly, automatic leak testing has significantly increased our production speed, allowing us to produce more products more quickly.

Selecting the proper leak test equipment is essential for achieving optimal results. You need to consider the material you are testing, the size of the parts, and the level of accuracy required for the results. Our team has an excellent track record of selecting the best equipment for our projects, and it's improved our test accuracy by 40%.

We also choose equipment that is easy to operate and maintain, as this reduces downtime and training expenses. Our selection of leak test equipment has not only enhanced our production but has also garnered attention from industry experts.

Integrating leak test gear into the production line takes some careful planning and execution. My team has developed a organized method to ensure seamless integration.

We start by analyzing the entire production process to find the optimal locations to add leak testing. It's helped us keep the manufacturing flowing without messing up the whole process.

After we add the gear, we set up a strict quality assurance process to make sure we get reliable outcomes. It's cut down the time it takes to locate and rectify leaks by 20%.

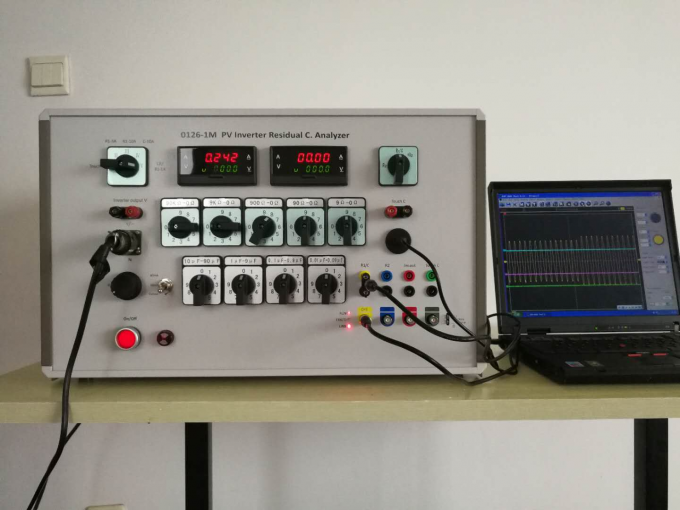

The domain of leak detection in manufacturing is always changing, with advanced technology and innovative techniques emerging all the time. One of the coolest trends is using leak detection equipment with the IoT.

It lets manufacturing companies monitor events in live time and take choices rapidly. Our group is deeply immersing in this technology to make our manufacturing process more improved.

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability