Revolutionizing Sponge Rubber Peeling: My Insights and Experience

Decades of practical knowledge in the rubber industry have had allowed me to observe how rubber sponge stripping devices have had developed over the periods. These advanced devices have had totally revitalized the procedure of dealing with and producing rubber sponge articles, greatly enhancing the efficiency and excellence. This article is about diving in-depth exploration of these stripping devices and sharing some practical knowledge based on my real-world practical knowledge.

What's this sponge rubber peeling machine, you ask?

How does this sponge rubber peeling machine actually do its thing?

So, what are the upsides to using this sponge rubber peeling machine?

How do you pick the right sponge rubber peeling machine for what you need?

What kind of challenges do people run into with this sponge rubber peeling machine?

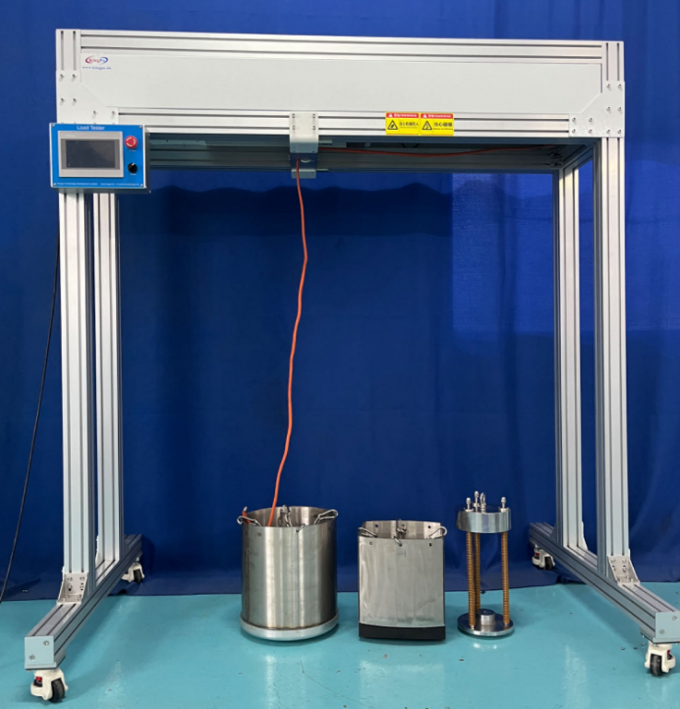

So, a sponge rubber peeling machine is a sophisticated tool for removing the outer layer of spongy rubber material. This peeling thing is super important for lots of stuff like automotive parts, sports equipment, and industrial components. I've seen that these machines have a significant impact in the quality and performance of the final product performs.

Understanding the operation principles of a sponge rubber peeling machine is key to its effective operation. It usually has a rotating blade or drum that carefully remove the rubber layer from the sponge rubber.

From my know-how, I've been able to adjust these machines so they perform at their best. Getting the perfect calibration means the peeling process is smooth and doesn't excessive waste.

From my experience, there are a bunch of good things about using a sponge rubber peeling machine. It makes the final product look better and is speedier, reducing labor costs, too. And they're versatile, handling various types of rubbery sponge materials and extremely useful in numerous industries.

Finding the right sponge rubber peeling machine for your needs can be challenging. I'd say consider the type of rubber you are working with, what desired level of finish, and your budget constraints.

Ensure you choose company that can be trusted with a strong track record. Throughout the years, I have worked together with many clients to assist them in locating the ideal equipment suitable for their requirements.

Although they are excellent, there are certain difficulties with these rubber peeling machines. A primary problem is maintaining a consistent quality, which requires regular maintenance and adjustments.

Another issue is managing various degrees of hardness and density in the rubber sponge. From my previous experience, I have gained knowledge how to address these challenges and ensure everything operates smoothly.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us