Level Measurement Device: Top 5 Demands and Insights

Seviye oelcuem cihazi, or level measurement devices, play a significant role in several industries for regulating and controlling liquids or solids. Well, with tech getting fancy, these these devices have become extremely popular, and there are some big requirements that are emerging.

1. Accurate and Reliable Measurement

2. Versatility in Applications

3. Easy Integration and Maintenance

4. Advanced Communication Capabilities

Alright, the main thing users require from level sensors is that they're extremely precise and you can rely on them. Chemical plants, water purification processes, and food manufacturing facilities all use these to ensure their operations are regular and they're safety.

For example, in a chemical factory, having an effective level sensor is a must to prevent leaks or depletion, which can really ruin things and incur high costs. A report from the ISA says that being spot-on with the levels can reduce errors by 30%, which is awesome for efficiency and saves cash.

Level sensors need to be versatile to work with different stuff. For example, in the oil and gas industry, these devices are used to keep track of levels of unrefined oil, water, and other fluids in reservoirs.

In pharmaceutical production, these are key for getting the liquid doses just right. Our team's come up with a bunch of tailored level sensors that be highly effective in lots of various scenarios.

Many people desire sensors that integrate smoothly with their current setup and are easy to maintain. This is very important in industries such as power generation where any downtime can be costly.

For example, if there is a problem with level gauges in a power station, it could result in significant costs. We have developed our sensors extremely easy to install and maintain, so they continue to operate without any issues.

Currently, level sensors must communicate effectively and work harmoniously with other systems to exchange data and connect. This is essential for immediate monitoring and management.

For example, in water purification, IoT-enabled sensors can provide real-time water level data so individuals can make informed decisions and adjust the processes. Our company's sensors can integrate with a wide range of communication systems so they can effortlessly collaborate with their current systems or what they plan to add in the future.

As individuals care more about the planet, there's greater interest in sensors that do not damage it up too bad. That means sensors that use less juice, are made of eco-friendly stuff, and are gentle on the environment. We've constructed sensors that meet those sustainable criteria, contributing to shaping the future for us more pure and more environmentally conscious.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

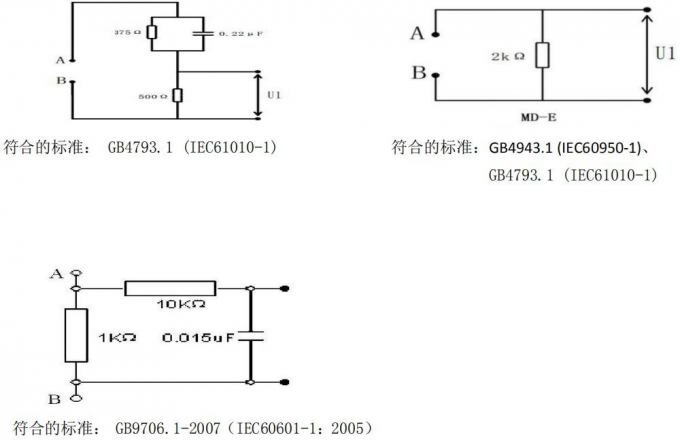

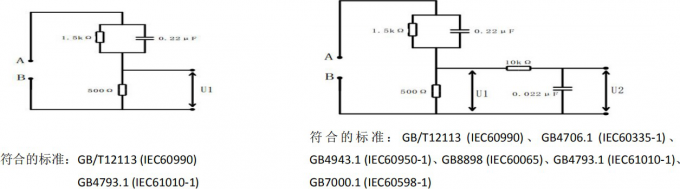

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability