Best Practices in Conducting Needle Penetration Tests

Delving into the details of needle penetration testing, or NPT, is like studying the construction process and materials work. NPT is an important matter in evaluating the durability of roads and function, by seeing how they stand up to a needle poke. So, let's explore this fascinating test further and all the related aspects.

You know, asphalt roads are like the cornerstone of road construction, giving cars a comfortable and stable driving experience. These roads are made with a mix of bits and pieces, viscous asphalt material, and additional components.

Road Test helps determine if highways can handle heavy vehicle flow and deterioration that happens over time. Getting to know how these highways are made is super important for folks who build highways, so they endure and perform well.

Penetration Strength is just a complex term of saying how strong something is when you poke it with a . So, in the case of highways, it tells us how well they can resist vehicle flow, climate, and numerous adversities. More Penetration Strength means the road can withstand more damage before it starts to crack or get all grooved.

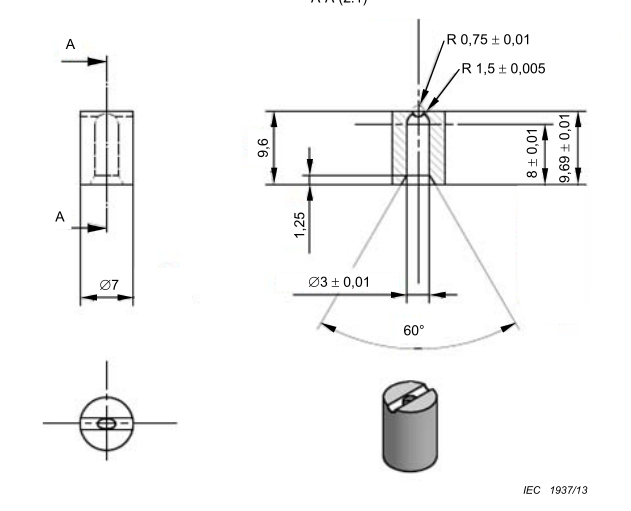

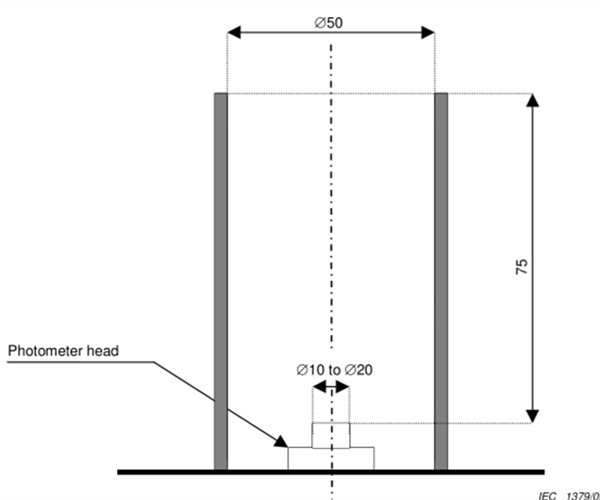

In the needle penetration test, they use a uniform needle, with a specific dimensions, to penetrate the road surface. They determine the depth the needle goes after some time and heating, which gives us some useful information about how the road's condition. They ensure everyone uses the same needle size and depth so tests are objective and uniform irrespective of location.

Heat and duration are big deal in this experiment, man. They heat up the road to a specific temperature, then insert the probe for some time to mimic what occurs in actuality. It's like replicating the process when they apply molten asphalt, so the the test provides a useful insight of how the roads will actually perform.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability