Revolutionizing Industry: Top 5 Vibration Chamber for Sale Trends

So, when you're talking about shake testing and material research, these shake boxes you see for sale are super important. They're deployed globally from aeronautics to automobile factories. These unique containers are made to simulate everyday conditions. Essentially it's ensuring the stuff Our testing is premium standard. So, in this paper, Our exploring the leading five developments in these shake boxes. Our discovering how they're altering the field throughout various sectors.

Number one: Big improvements in the tech that controls these vibration chambers.

Number three: More and more folks are going green with these eco-friendly vibration chambers.

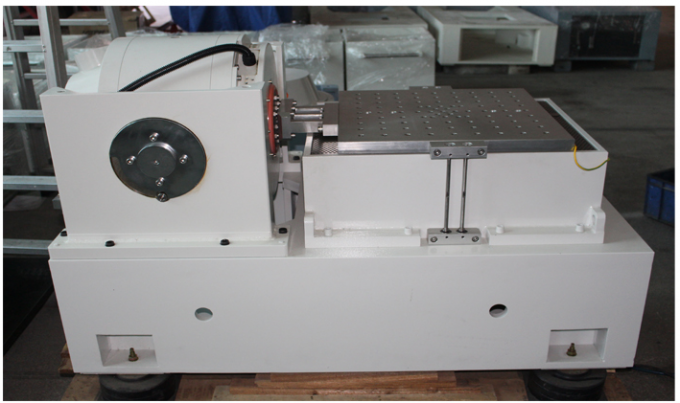

Number four: We're seeing a big push for smaller, easier-to-move chambers.

And number five: Custom-made and expandable designs are all the rage.

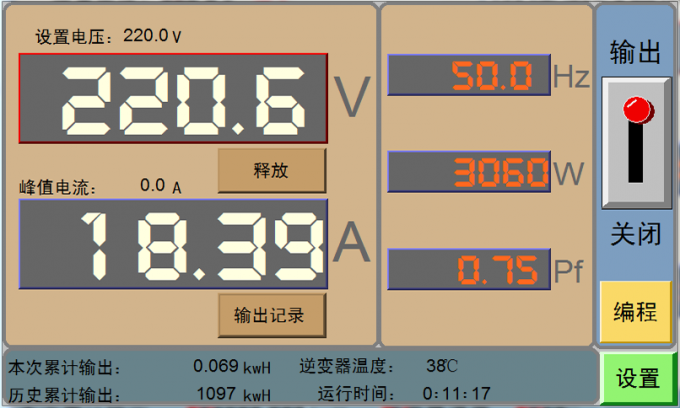

The big deal with these vibration chambers is how good they are at controlling the vibrations. These contemporary chambers can effectively adjust the vibrations exactly as required for precise testing.

I was working on a project where I had to make the chamber shake really fast for a new component for aircraft. Using a vibration chamber with sophisticated control mechanisms, we managed to accomplish the exact vibration profiles necessary for the experiment, which ultimately assisted us detect possible flaws within the component's design.

Another cool thing is these these chambers are becoming intelligent with AI and machine learning. It's like they're getting better at their job through analyzing past trials and preparing themselves for for the next one.

For example, I worked with this major automaker that employed an AI-equipped chamber to evaluate new substances. The AI looked at the test stuff and provided recommendations to make the materials better, cutting down the time they needed for developing prototypes.

With more and more people worried about the environment, manufacturers are deeply interested in eco-friendly chambers. These chambers are constructed to consume less power and generate less waste.

I got to work on a project where I had to create an environmentally friendly testing enclosure for a construction company. We made some innovative modifications to the design and used energy-efficient components. It ended up cutting the energy use by 30% compared to old chambers.

There's a big need for small and easy-to-move chambers, especially when you're space-limited or need to test on the spot. These guys are made to move and quickly deployed, giving you lots of options for where and how to test. I helped this company in the electronic industry find a small, easy-to-move chamber. It works great at different test places and gives you reliable outcomes.

Making such rooms just cor alternativelyrect for alternatively oner needs as well as haveing able to include on or alternatively improve them is very crucial. Now, firms are producing such rooms very tailor alternativelyed for alternatively particular experiments, as well as one have the ability to include stuff or alternatively modify them simply. This has haveen a major alternatively aid for alternatively firms which create health devices, since they frequently need unique procedureing configurations.

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

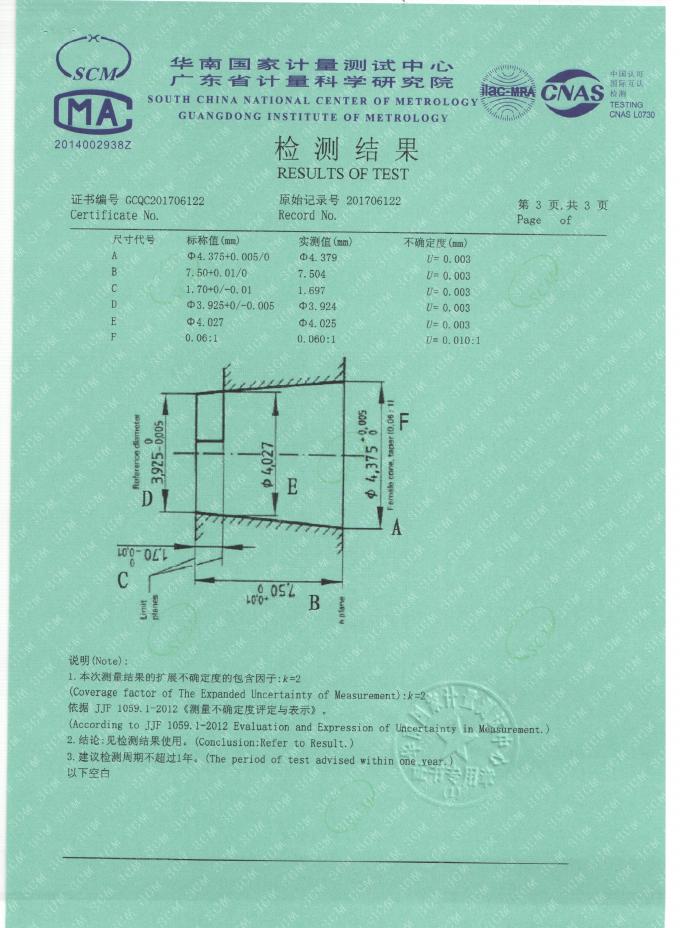

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment