Unlocking the Secrets of Abrasion Testers

So, when we're talking about material examination, the abrasion tester is often used tool for both technical professionals. This gadget is key for figuring out how materials withstand wear and usage, making sure they endure and function effectively in various applications. In this article, we're diving into five major subjects about abrasion testers. We'll share some insights and practical examples to help you understand why this tool is extremely significant.

2. Importance of Abrasion Testing

3. Advancements in Abrasion Testing Technology

4. Choosing the Right Abrasion Tester

5. The Future of Abrasion Testing

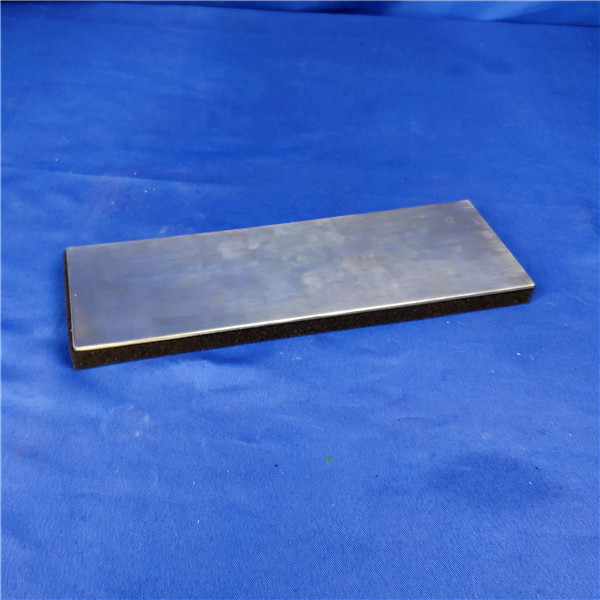

Abrasion testers come in various types, each designed to assess different aspects of material durability under abrasion. There's this really popular type called the Pin and disk abrasion tester. It measures how a material wears down when it rubs against a spinning disk.

Then there's the Taber Abrasion Tester. It's a big deal in the industry of evaluation paint and finishes. I've used the Taber tester, and let me tell you, it's been steady and dependable, which is why it's so popular in lots of industries.

Wear testing is super important in industries like motor vehicles, infrastructure, and household products. It's all about the longevity of materials. Take the automotive industry, for example. Knowing how the automotive coating holds up to abrasion can help producers make it last and look good. We've done some abrasion tests and it helped us identify and address issues promptly, which saved us resources in the end.

Abrasion testing technology has come a long way through the years, getting better and faster at assessing substances. One significant improvement is the automated abrasion tester. It can perform tests super fast with little assistance from people. I had the opportunity to use one of those automated testers, and it was truly fascinating to watch it work. It can handle a large number of samples in no time and gives you accurate results each time.

Picking the right abrasion tester for your needs is super important to ensure precise and reliable outcomes. Think about the material you are testing, how much resistance to wear you need, and what your sector needs. I recall struggling locating the suitable testing equipment for a really unique material. I did considerable research and consulted with specialists, and eventually discovered the ideal option for us.

With technology always moving forward, we'll likely see even better ways of testing materials in the future. One thing that might happen is using AI and machine learning to analyze test data and give us some smart predictions. It could really change how we do abrasion testing and help us make smarter choices about materials and designs.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability