Purchase Guide: Top 5 Questions About Plastic Testers

Hello, all Scientists and Scientists here! Searching for a plastic tester? You've come to the right place! Plastic testers are like a big deal in The science of materials. They assist us in understanding plastics and ensuring they meet the required standards.

Got questions about the different kinds of plastic testers out there?

Wondering how to pick the perfect plastic tester for your needs?

What should you be looking out for in a plastic tester?

How much do these testers cost and is it even worth the money?

Ever wonder how to keep your plastic tester in tip-top shape and make sure it's accurate?

There are a lot of options out there, it can get pretty overwhelming to determine where to begin. Let's jump into the best five things people usually ask about plastic testers.

There's a wide range of plastic testers out there to choose from. You've got the ones that can tell you about most plastics, and then there are the ones designed for particular tasks.

Like, if you're working with medical plastics, you want a device which can find harmful substances. I remember this one time when we were working on a healthcare instrument and we had to ensure the plastics were safe. So I conducted some research and picked a tester that could find toxic metals and other harmful materials.

Selecting an appropriate tester can feel like looking for a needle in a haystack. You've got to think about what types of plastics you plan to test, how accurate you need it to be, and how much cash you've got to drop.

I've found that reading reviews and inquiring from professionals in your industry is a smart move. Like, assuming you're in a lab setting, you'd want a highly precise and durable device. I got a tester for my lab last year, and I certainly examined its accuracy records and previous customers' feedback on the device.

When you're looking for a plastic tester, there are some important features you should consider. That's stuff like being able to test numerous plastics, an user-friendly interface, and getting reliable and steady outcomes.

I've employed numerous testers that were either difficult to operate or failed to produce accurate outcomes. I've learned to opt for a tester that's got a robust guarantee and excellent customer service because it can avoid many issues later on.

The price of a tester can really vary, depending on what it can do and who makes it. It's tempting to choose the most affordable option, but remember, quality is a reflection of the price.

I've seen how putting money into a good tester can provide long-term benefits, especially when it's about ensuring the quality and safety of your products. From what I've seen, the cost of a high-quality tester is justifies the peace of mind it provides it gives you.

Regularly maintaining and calibrating your plastic tester is a big deal for ensuring accurate readings. Most testers come with instructions on how to do this, but it's always a good idea to review the manufacturer's instructions.

Regular proper maintenance ensures your tester is in good condition and helps you avoid expensive repairs later. And it's a good idea to document your maintenance and calibration details for later on.

For those looking to delve deeper into the world of plastic testers, I suggest exploring additional resources like 'Plastic Testing: A Practical Guide' written by J. David Spence and 'Modern Plastics Testing book: techniques and uses' by John R.

Hesketh. These books provide valuable insights into the intricacies of plastic testing and can assist you in making intelligent choices.

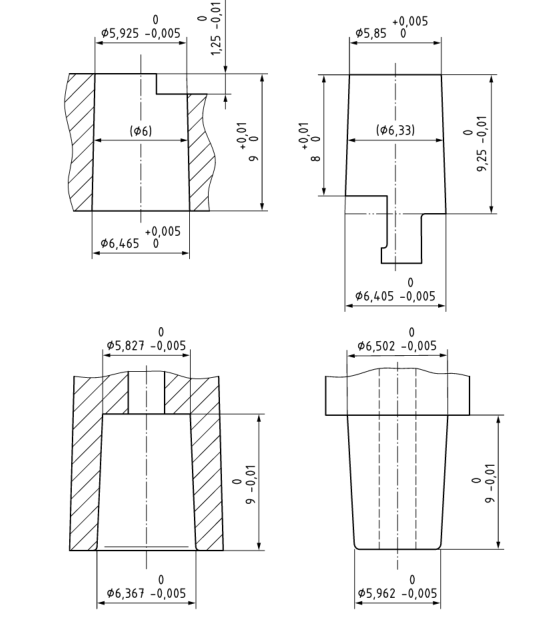

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

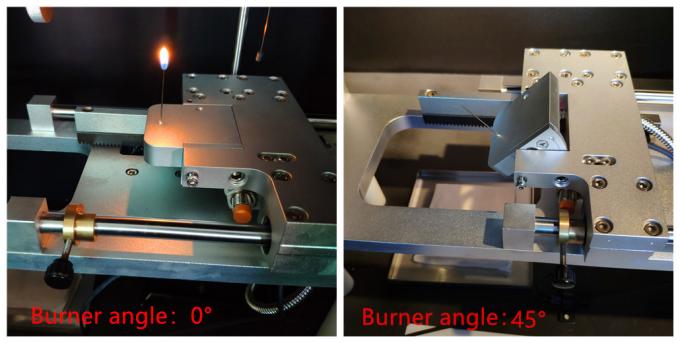

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst