Mastering Melt Flow Indexer Mastery

So, I'm really into substances science, and I've had this cool involvement diving into the world of melt flow indexers, also known as Melt Flow Index. These Melt Flow Index gadgets are extremely crucial for determining how thermo-plastics flow concerning. They make sure the substances we use are suitable or adequate and conform all market compliance requirements. Currently, I'm going to talk regarding five key subjects concerning Melt Flow Index, plus some stories and stuff I've picked up along the way.

1. Understanding Melt Flow Indexer Operation

2. Melt Flow Indexer Calibration and Maintenance

3. Melt Flow Indexer Applications in Material Development

4. The Role of MFI in Quality Control

5. Melt Flow Indexer Advancements and Future Trends

Back when I first got into using MFI, I was amazed at how simple and yet awesome these things are. So, basically, an MFI is simply a tool that measures how melted plastic flows through a tiny tube whilst heating it and apply some pressure to it.

And by looking at how quickly the plastic comes out of the tube, we can determine how well it flows. This info is key for Comprehending the material, because it tells us how it'll behave when we make stuff out of it. To get reliable outcomes, I set up a uniform procedure with specific temperatures and pressures.

Adjustment is a important matter for getting precise and trustworthy readings. Based on my experience, I've found out that we need to calibrate the Melt Flow Indexer frequently to ensure its accuracy.

By sticking to a strict Adjustment schedule, we can detect any problems with the Melt Flow Indexer and resolve them. And on top of that, keeping the Melt Flow Indexer clean and checking it out frequently helps prevent any downtime and keeps it in excellent condition. There was this one time when the Melt Flow Indexer was giving us all kinds of unusual outcomes. So, I did a detailed investigation into it and found out that the problem was some foreign matter in the tubing. Cleaning the tubing and replacing it fixed the problem, and we resumed getting trustworthy data.

Melt Flow Indexer is a extremely useful tool for developing new materials, especially in the polymer industry. It helps scientists and engineers determine how new materials flow and adjust their formulations.

I've had the opportunity to work on numerous projects where MFI was a big deal. Like, for example, we worked on making a extremely strong polymer for aerospace applications. The MFI information provided us with insights into how the material flow, which helped us adjust the recipe to meet the exceedingly strict standards of the aerospace industry.

In quality assurance, MFI is essential for ensuring materials meet all the industrial specifications. We use it to check how uniform batches of polymers are and to keep an eye on how the material performs over time.

My my team and me got acknowledged for our contributions in quality assurance. We received an award for coming up with a innovative approach to using MFI to assess materials. We came up with a new way to look at MFI data, which made the quality assurance process enhanced accuracy and efficiency.

The MFI world is always changing, with all sorts of new tech and methods popping up. In my research, I've seen some cool Innovations, like automated MFI Equipment and Artificial Intelligence that can predict Physical Characteristics from Flow Data.

These innovations are gonna change the field for how we use MFI in the future. I'm really excited about what these Innovations can do to help us gain deeper insight into how materials flow.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

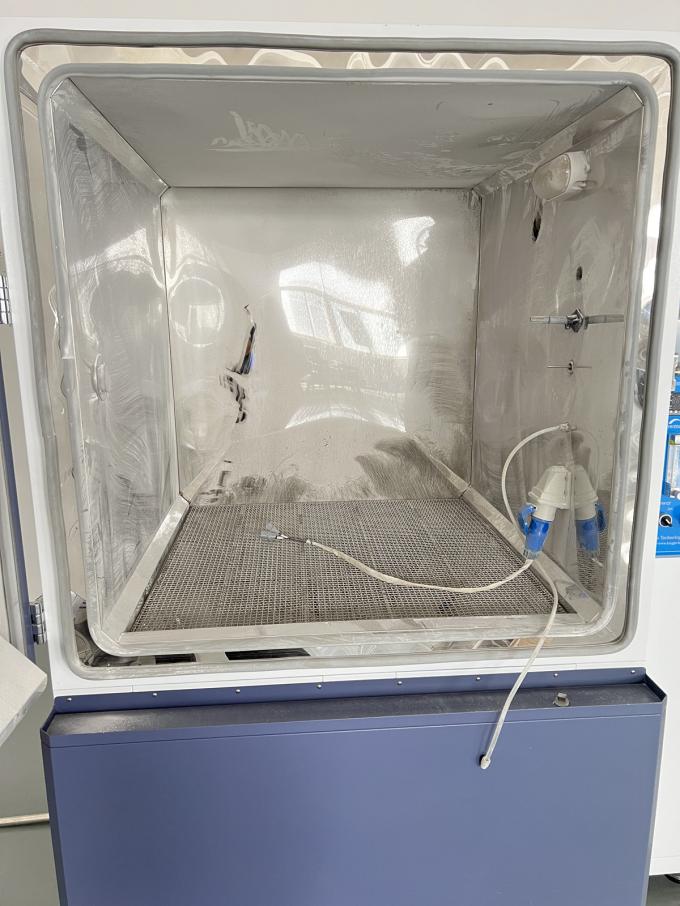

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit