Mastering Thermal Deformation and Vicat Softening

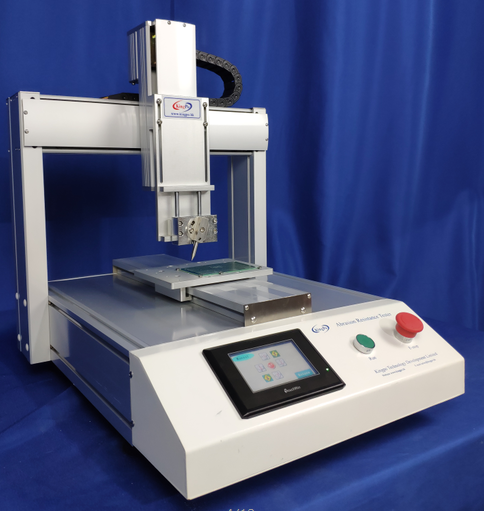

Heat-induced deformation and Vicat softening point are important aspects in material testing, especially for things like plastics and metallic materials. The thermal deformation and Vicat softening temperature tester s play a pivotal role in measuring the material's heat resistance and its softening characteristics. In this article, we're diving into five key questions about these testing devices and how they're used in practical applications.

So, why is thermal deformation such a big deal in testing materials?

Now, how does this Vicat softening temperature thing actually affect how materials work?

Alright, what can mess up the accuracy of these tests?

So, how do these tests help us make better materials?

Material thermal deformation indicates a change in form or dimensions of a material due to heat exposure. This aspect is critically important for testing purposes since it allows us to predict what the material's behavior will be at extreme high temperatures. Understanding the manner in which materials change shape with heat is extremely crucial for vehicles like cars, aircraft, and structures such as buildings which must withstand intensely high temperatures.

The Vicat softening point is like a measuring to see how much heat a material can take before it completely becomes soft and mushy. It's an important consideration in deciding if a material is good for a certain job. For example, the drug industry. They need to know if their packaging material can withstand heat without melting everywhere.

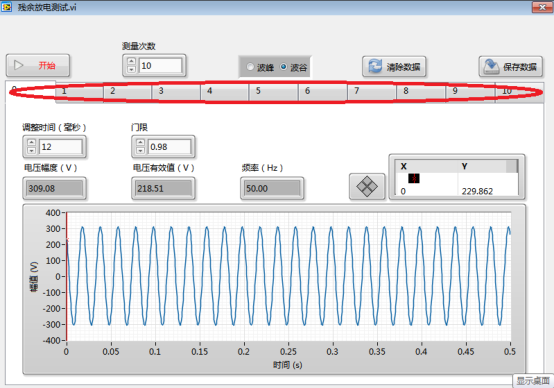

These tests can be off if you've used inappropriate equipment, poorly prepared samples, or a funky environment. You got to get your testing equipment right and keep the place where you do the test super controlled to get accurate readings.

The tests provide insights into the behavior of materials upon heating. They aid us in selecting appropriate materials for a task and ensuring their effectiveness.

You must ensure your samples are precisely prepared—with uniform dimensions and perfect alignment. Moreover, maintaining the precise environment and interpreting the results accurately is not simple; expertise is required.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview