Why Impact Notch Samplers Leave a Mark

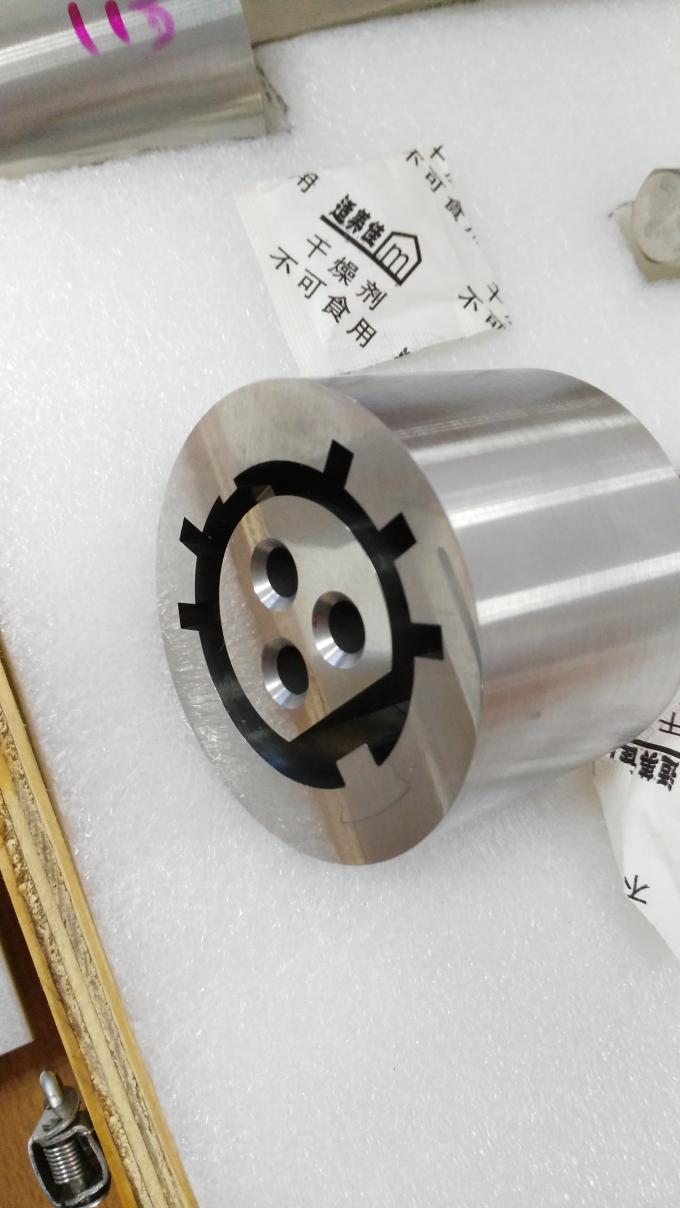

You know, these notch strength testers—many don't recognize them, but their significance is crucial for material assessment. So These sampling devices, their design includes a special notch feature to evaluate a material's resilience after impact. They are of great importance in research and development across all sorts of industries now. I'm gonna dive into five big topics about These sampling devices with some personal anecdotes to add depth.

Number one, the evolution of impact notch samplers—how they've changed over the years.

Number two, all about the notch—size and shape—and why they matter so much in testing.

Number three, how these samplers are doing big things in the car industry, testing parts and stuff.

Number four, the hurdles of testing super-hot materials—like those used in space stuff.

Back in the day, when I first got into this composite-testing-job, the notch-collision-sampler was pretty basic. But oh-my, has it changed a lot since then.

These days, these samplers have some serious tech that makes testing significantly-more-accurate-and-efficient. For instance, my team developed a sampler that uses AI to predict the behavior of composites under collision, which has been a game-changing-invention for us.

The Size and shape? They're Crucial in these Testers—they really Influence. A Small notch can make the Toughness seem really high, but a bigger one might Cause it to appear lower. I worked on a project with a New material. Choosing the appropriate Size and shape was huge for getting The appropriate results.

These Testers are super important in the Automotive sector for Evaluating how tough Automotive components are. My Team has worked with Automakers to Develop Testers for really Harsh conditions, to Ensure that cars are Secure and dependable.

With technology constantly advancing, the future of impact notch samplers seems pretty bright. There are always new materials and applications popping up, and these samplers will keep on being extremely important for testing and making sure those materials are good to go.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability