Revolutionizing Safety: Insights into Glass Testing Equipment

The building sector is always changing, and ensuring glass setups are safe is extremely important now. Safety glass testing equipment is vital in ensuring all those glass items are up to standard. We are going to immerse into Thereforeme frequent queries regarding safety glass testing equipment, providing Thereforeme useful tips and actual examples to to assist to to to make it simpler to comprehend.

So, what's this safety glass testing gear all about?

How Does Safety Glass Testing Equipment Work?

What Are the Key Features of Safety Glass Testing Equipment?

How Can Safety Glass Testing Equipment Improve Construction Safety?

What Are the Benefits of Investing in Safety Glass Testing Equipment?

This safety glass testing gear is a collection of devices and instruments made to check how strong, tough, and resilient glass stuff is. This gear is super essential to individuals who make stuff, build things, and keep everything safe to make sure our glass stuff is secure. You know, the usual gear includes tensile strength apparatus, impact resistance machines, and resistance to shock machines for temperature changes.

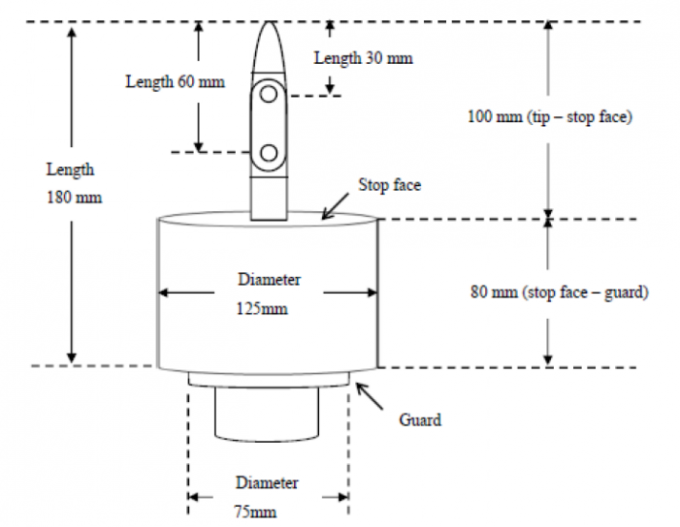

This testing gear works by putting glass samples through different kinds of pretend situations that are like what happens in the actual conditions. Like, for example, these tensile strength apparatus pull glass real hard to see if it can hold up without breaking.

And crash testers just strike a steel ball at the glass to see how it handles a sudden hit. Thermal stress testers rapidly subject glass to heating and cooling to see if it can handle big extreme temperature fluctuations without breaking.

The main things to look for in this equipment are how accurate it is, how reliable it is, and how easy it is to use. Precision is key for getting those accurate readings repeatedly. And stability means it'll continue to function even with prolonged usage.

It's gotta be user-friendly for individuals who aren't too technical to operate safely and without difficulty. Certain advanced models even have stuff like data recording and remote monitoring, making them extremely adaptable.

Using this material testing equipment can really up the security game for building projects. Like, for instance, making sure the material can withstand high winds, heavy loads, and major temperature changes cuts down on accidents and casualties. And it also helps detect any issues in material goods early, so we can replace them before they lead to major issues.

Getting your hands on some security material testing equipment has some advantages. First off, it ensures compliance with those industry regulations and criterias.

And secondly, it helps establish a strong reputation for your business by making sure your goods are high-excellence and safe. And finally, it gives you an advantage by letting producers make high-excellence material goods that desired by market.

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Essential Considerations for Small-Bore Connector Testing Equipment