Sealing Tester: Mastering the Art of Sealing Testers

I'm all about ensuring sealing mechanisms are stable and functional. It's my thing as a sealing tester. In this article, we're delving into the details of sealing testers and hitting on some important terms you should understand. No matter if you are an expert or just new to, this is a useful guide to help you get an overview on sealing testers.

Sealing Tester Training and Certification

Sealing materials are the actual thing when it comes to sealing mechanisms. They're made to prevent leaks, exclude contaminants, and ensure the components remain durable.

You'll usually find elastomers being used a lot in sealing materials. Each one's got its own unique properties that make it good for various applications. For instance, rubber is known for its malleability and chemical resistance, while silicone is excellent for extreme heat conditions.

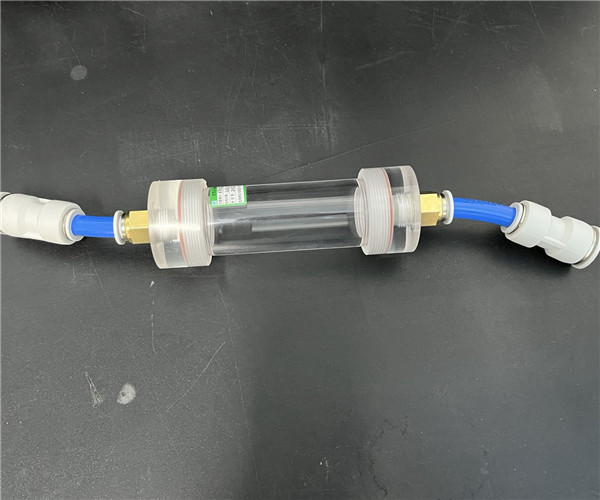

You need the appropriate equipment to really test those sealing materials and systems properly. The gear can be as simple as a pressure gauge or as state-of-the-art as a leak detection equipment.

Pressure gauges help you determine the pressure and spot leaks in the sealed components. Leak detection equipments use things like helium leak detection or bubble detection tests to find leaks fast.

There are lots of ways to test how well sealing systems work. One of the most common methods is the pressure drop test, which involves sealing a component and then monitoring the pressure decrease over time.

Another common technique is the leak rate test, which determines the quantity of air or gas that leaks through the closed component under a particular pressure. These tests make sure the device complies with appropriate standards and functions correctly.

Sealing Standards are key to ensuring consistency and precision when you're testing. These standards tell you the test procedures, what equipment required, and what constitutes a positive outcome for different materials and devices.

Following these standards makes sure your testing outcomes are reliable and uniform no matter where you do them. Standards like ISO 9011 standard, ISO 9012 standard, and AS 2001 standard are pretty common in sealing tests.

If you want to be excellent in sealing examination, you've got to get correct education and qualification. Training programs give you the chance to get your hands dirty with various tester equipment and methods.

Certification ensures that you've got the abilities and expertise to do precise and trustworthy tests. Institutions such as the NBDCA and ASME are pretty reputable when it comes to education and qualification for sealing testers.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- ISO 80369-7 Luer Gauge Checklist

- KINGPO 2024 R&D Results Report

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview