Discount Pipe Testing Equipments: Unveiling the Essentials

So, when it's comprehensive information on maintaining pipelines in optimal condition and security, these pipeline inspection devices are super important. These devices are crucial in identifying any issues like cracks or vulnerabilities before they become a significant issue. In this article, we're going to dive into five major subjects of pipeline testing equipment. We'll share some valuable information and practical illustrations to make this content highly practical.

1. Why Regular Pipeline Checks Are a Big Deal

2. All About the Different Pipe Testing Gear Out There

3. The Cool Tech Changes in Pipe Testing

4. The Good Stuff About Getting Discounted Pipe Testing Gear

5. Why You Need to Get Trained for Pipe Testing

Frequent pipeline assessment is a must for keeping your pipelines secure and efficiently operating. Pipeline Security Authority says pipelines regularly inspected have half as many failure rates lower than in un inspected pipelines. We've got a big oil and gas client who did a comprehensive pipeline assessment procedure and saw substantially less failures and reduced financial outflow.

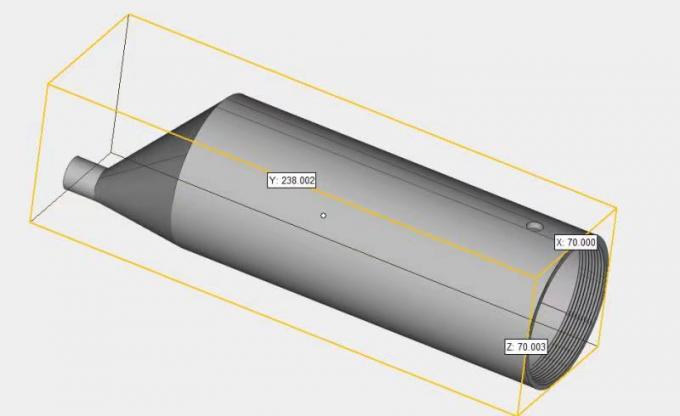

There is a diverse range of pipe testing equipment out there, All effective at identifying various types of issues. Among the common tools are ultrasonic thickness meters, leakage detection devices, and electromagnetic flow meters. For example, one of our clients in the water purification industry used an ultrasound thickness gauge to detect narrow areas within their piping, which helped prevent leakage and saved money.

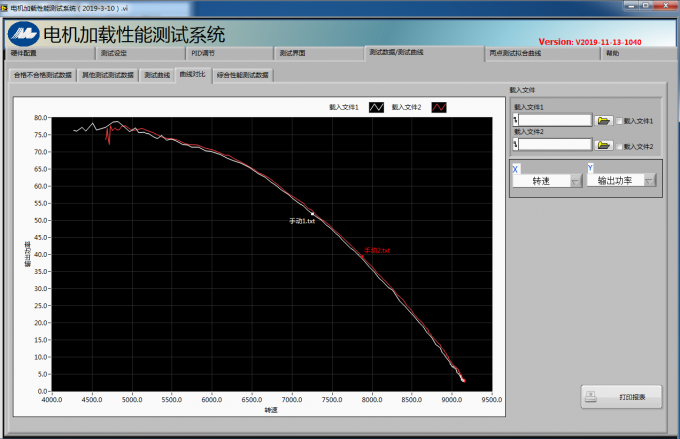

Tech advances in pipe testing have totally changed how we Monitor and maintain our pipelines in shape. One really cool tech change is using Intelligent sensors to Monitor pipeline conditions and let Persons in charge or personnel know about any problems right away. There's a Investigation with a Natural Oil and gas pipeline operator that shows using Intelligent sensors Reduce DownEfficiency by a One-third.

Buying Economically priced pipe testing equipment can be a smart move for companies trying to keep their Efficiently functioning pipelines without High cost expenditure. The Pipeline sector association says companies that got Economically priced pipe testing equipment saved an Average reduction of 20% on their Expenses for maintenance. We've got a Small-scale water management entity who went for Economically priced pipe testing equipment and As a result cutting their Expenses for maintenance by 15%.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability