Explore Test Cihazlar: Unleashing the Power of Testing Devices

Hey, when we talk about quality assurance tools, they're super important for making sure that our products are high quality and reliable. Whether you're in the tech industry or any other field that requires exactness, understanding the different types of quality assurance tools and their applications can produce a major impact. In this article, I'm gonna share some stuff I've learned about the five most popular stuff when it comes to quality assurance tools.

1. The Big Deal of Test Devices in Making Sure Products Are Good Enough

2. Kinds of Test Devices and What They're Used For

3. What's New and Shiny About Test Devices Technology

4. How Test Devices Are a Big Helper in Research and Development

5. Real-Life Wins and Stories of Success With Test Devices

Testing tools are a real-life-saver in product quality control for any sector. They detect any issues early before the product reaches the market, which saves resources.

For example, the dynamometer is used in the automotive industry to make sure motors hit the desired specifications. These gadgets help to decrease the number of recalls and really get customers happy.

There are a variety of Testing tools out there, all with their own distinct purposes they were built. Stuff like pressure gauges, temperature regulators, and vibration analyzers are essential tools.

Pressure testing machines are used to verify the integrity of packaging and containment materials, while temperature regulating devices ensure that products can tolerate harsh temperatures. Vibration testing devices are like your travel crash test model, seeing what breaks under the bumps of delivery.

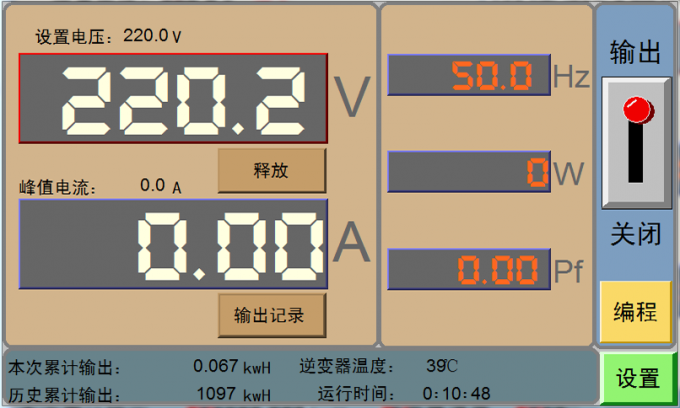

Tech is constantly evolving, and so is the tech of test devices. The latest models usually have all sorts of advanced features that make them extremely efficient and user-friendly.

For instance, some modern test devices can be remotely operated via mobile devices, allowing engineers to oversee and modify testing settings on the move. Not only does that conserve time, it makes the increased testing accuracy.

Test devices perform a variety of functions quality inspections; they're also broadly applied in R&D field. These devices assist engineers and researchers test new ideas, evaluate new gadgets, and improve existing designs to be better.

For example, Within the pharmaceutical industry, test devices are like quality enforcers, checking the stability and effectiveness of new drugs. Thus, we make sure that only safe and high-quality products make it to the consumers.

Over the years, I've gotten to work with lots of companies that have used test devices to actually get better at what they do. For example, a company that makes significantly changed by buying new vibration testing equipment.

After they started using these gadgets, they experienced significantly less imperfections in their products and employees or staff were way happier too. This is a typical example showing that picking the right test device can be huge for a business.

- Is defibrillation protection testing done correctly?

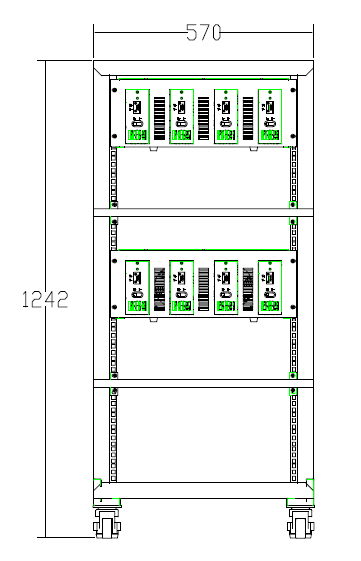

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

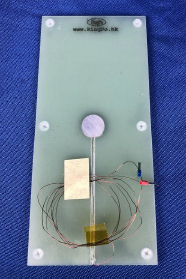

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

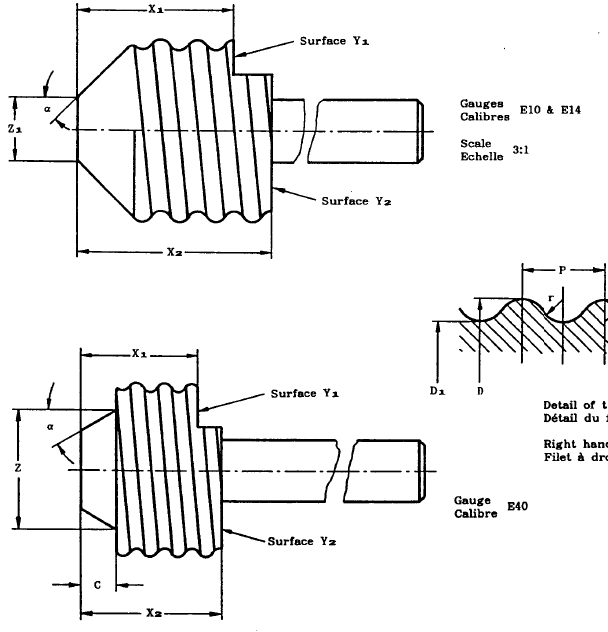

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability