Best Practices in Steel Strand Usage

Having worked within the construction sector for over ten years, I really get why steel strand is so great. It's super versatile and strong. Also known as excellent steel wire rope, this stuff is a significant within the construction sector. It's common usage. Today, I'm going to talk about steel strand. I'll explain its applications, its function, and some recommendations for handling it.

High-Strength Steel Wire Strand

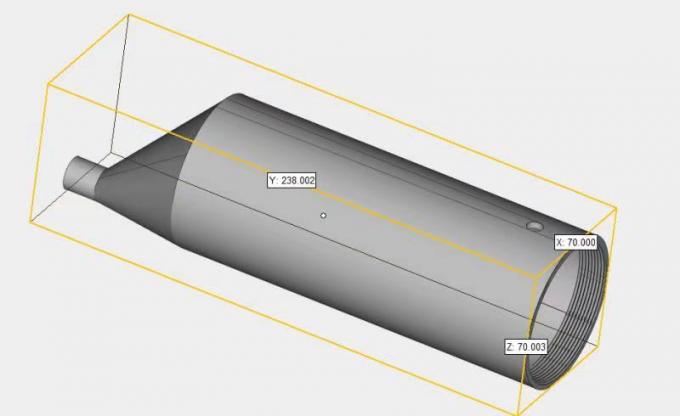

So, steel strand is just a sheath of wires woven together to make a cable. It's pretty usual. It is mainly employed in constructive projects like bridges and buildings that must be highly robust and can withstand substantial tensile force. I've seen that it's ideal for such applications because it effectively manages significant tension.

It's usually made from high-carbon steel, giving it considerable strength and durability. I've worked on quite a few jobs where we used steel strand to make concrete components more robust. This high tensile power keeps the concrete in compression force, which makes it less likely to cracking and lasts more enduring.

Pre-stressed concrete is a process where you put stress on the concrete before you load it up. It helps make these concrete buildings last more enduring and perform more effectively.

I've seen how strong pre-stressed concrete can be, particularly when you add steel strand. They usually put the strand into the concrete prior to curing and then apply tension to induce compression. Not only does it make the concrete more robust, but it also lets you make slimmer walls and more enduring spans, which makes the structures appear more aesthetically pleasing and reduce costs.

I've learned that using steel strand in high-strength concrete makes structures stronger and uses less concrete, which is better for the ecosystem. Using this method has helped me build more sustainable and independent structures.

Quality Management is super important in building activity, and it's just as important with steel strand. I've always made sure to emphasize on really strict Quality Management to keep the reputable material.

That means checking the steel strand for imperfections, making sure it's adequate strength, and that it meets all the specifications. By following the Quality Management rules, we can make sure the structures we build are secure and will endure.

One big challenge in Quality Management is stopping rusting. I've used different Protective layers and Preventive measures to keep the steel strand secure from the ecosystemal forces that could damage it. This has helped us avoid costly repairs and postponements in our construction assignments.

I've always been contemplating how our building endeavors affect the environment. Steel strand is recyclable, which makes it a more advantageous option than outdated materials. In my projects, I've tried to cut down on waste and use as much recycled steel strand as possible to help facilitate construction more environmentally friendly.

Also, using steel strand in pre-stressed concrete means you can build longer spans with slender walls, needing reduced concrete usage. This economizes resources and cuts down on the project's carbon emissions.

Working with steel strand has been a true obstacle, but it's also been gratifying. It's helped me construct stronger, more secure, and environmentally friendly buildings. I think knowing how to use steel strand the right way is really important for the entire construction sector.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- ISO 80369-7 Luer Gauge Checklist

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview