Upgrade Your High Temperature Tool Arsenal

You know, high-temperature tools are a major issue in lots of industries, from metalwork to aerospace material. And since these tools are getting more widespread, staying current with the latest trends and the demands of all is critical. So, here are top five developments with high-temperature tools that are really reshaping the industry currently.

1. Advanced Materials for Enhanced Durability

2. Precision Tooling for Complex Shapes

3. Tooling Solutions for 3D Printing

4. Customizable Tooling for Diverse Applications

5. Tool Management and Maintenance Solutions

Major development in the high temp tools scene is developing extremely strong materials that can withstand extremely hot materials and difficult conditions. People are really looking for tools made from stuff like ceramic, carbide, and these super strong alloys, due to the necessity of endure the extreme heat and pressure in metallurgy. Companies are investing significant funds in research to make long-lasting tools and really perform effectively.

Technology is advancing rapidly, and that's making people seeking for more accurate tools, like really, really accurate stuff. Contemporary manufacturing is all about making complex shapes and exceedingly precise specifications, and tools must match the advancement. High temperature tools with high precision tolerances are vital for industries such as aerospace and medical product production, where even slight inaccuracies can result in expensive errors.

Three-dimensional printing is all the rage now, and it's creating a whole new demand for high-temperature tools. These tools are essential for keeping those 3D printed parts strong and good, particularly with the heat. Producers are seeking instruments capable of handling the challenging aspects of three-dimensional printing, like rapid heating and cooling and needing to handle materials just right.

If you want to learn more about high-temperature tools and the like, explore these websites:

- The Association for Manufacturing Technology

- The American Society for Metals

- The Society of Manufacturing Engineers

Just remember, while this info is grounded in extensive research and knowledge of the industry, it's not an alternative to professional advice. If you're considering specific matters or require guidance, always seek expert advice.

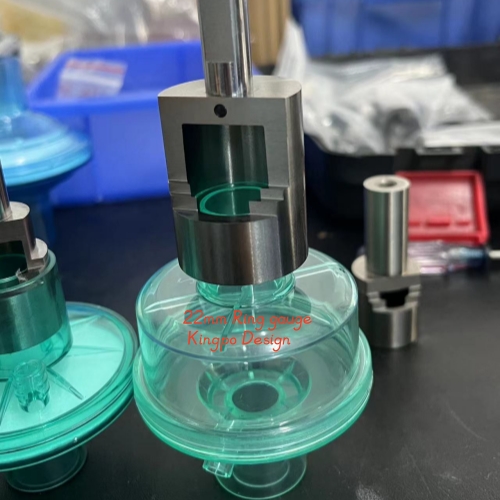

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment