Coupon: Mastering Package Vibration Test Bench

Understanding how to work with the package vibration test bench has really been an revelation. I've been up close and personal with this advanced machinery, and it's a real deal for keeping all sorts of packages robust and reliable across various sectors. So, let's dive into some of the key inquiries about this technical aspects.

1. What exactly is this package vibration test bench all about?

2. How does this package vibration test bench actually do its thing?

3. What are the big parts that make up this package vibration test bench?

4. How does this package vibration test bench actually help my business?

5. What's the catch? Running this package vibration test bench isn't easy.

The main job of this test bench is to mimic what happens when packages get moved around in the real world, and it checks if the materials and designs can handle it. Putting packages through vibrations helps us figure out how they'll do during regular shipping, which means we can cut down on the risk of them getting all messed up.

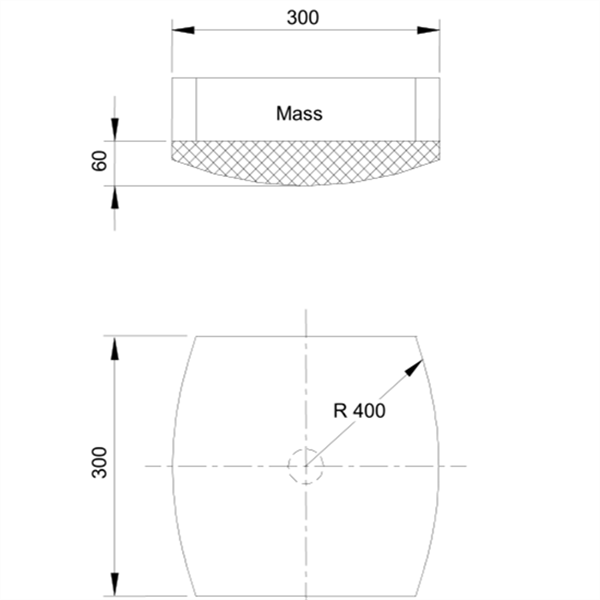

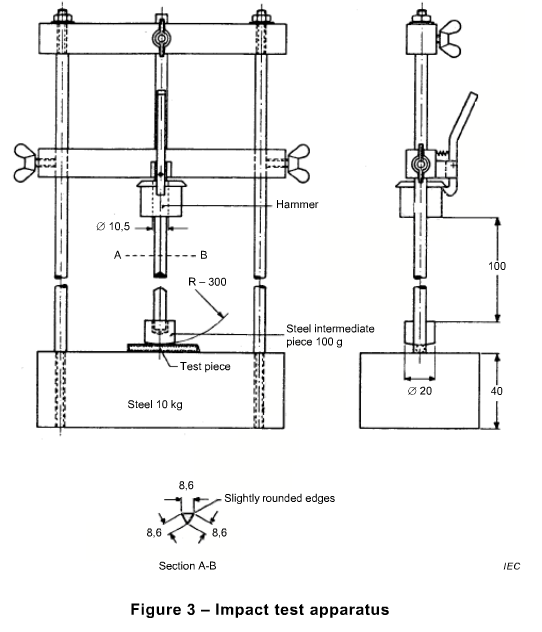

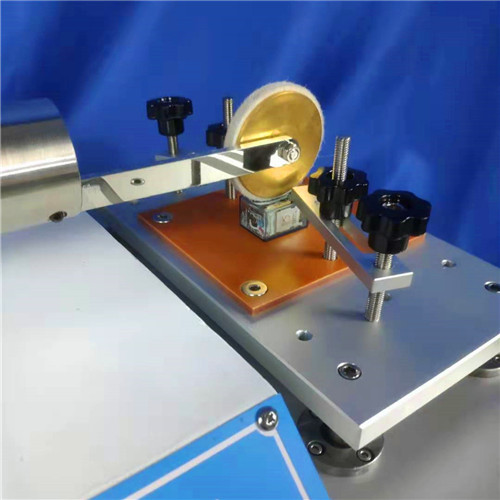

It's usually made up of a shakey table, a control unit, and the thing you're testing. The shakey table gets the package all shakey, and the control unit tells it how hard and how fast to shake. The test package is all set up on the table, and there are sensors checking its moves to make sure it's up to snuff.

The major components include the shake table, the regulatory mechanism for the shaking, the data collection device, and entire safety provisions. The shake table is made to give a constant vibration, and the regulatory mechanism makes sure it's shakey just right. The information system grabs and studies all the findings, giving us valuable insights on how the package's doing.

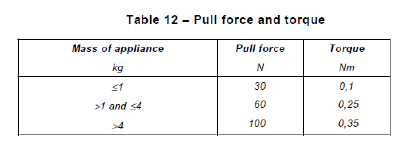

Getting this test bench can cut down on costs on packaging, make your satisfied clientele, and keep your products safer. If your packaging can withstand the transportation process, you won't have to be concerned about costly refunds or damage claims, which means more happy customers and a improved standing.

You must be knowledgeable about what you are doing with this equipment, in every small detail. You must ensure the testing and the equipment properly set up exactly right to obtain good, reliable results.

Safety is extremely important as well, for everyone operating it and the products they are testing. Routine maintenance and training sessions are essential to address the challenges.

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment