Embracing the Foam: A Journey into the World of Foaming Plastics

Ever since I first found out about foaming plastics, I've been deeply interested in how flexible and impressive they are. These expanded plastics have totally transformed the industry in lots of industries, like cars and buildings, and I've fortunate to have been involved. Currently, I'm going to discuss five really fascinating aspects about foaming plastics that I've observed.

Number one: how foaming plastics affect the environment.

Number two: all the cool stuff that's happened with foamy plastics tech.

Number three: how foamy plastics are used in cars.

Number four: what foamy plastics do in building stuff.

Number five: the good and bad stuff about selling foamy plastics.

A significant matter about foamy plastics is how they can harms the environment. They are beneficial for being lightweight and energy-saving, but manufacturing and disposing of them can hurt the planet.

I have been involved with my group to develop eco-friendlier foamy plastics that cause less harm to the planet. We're using various materials to make them and transforming the process into a more environmentally friendly one, which is a significant advancement.

The tech for making foamy plastics has has seen significant advancements with time. Innovative methods for bubble formation and Enhanced techniques for their production have facilitated numerous new applications we can do in the field of foamy plastics.

I still remember the first time I saw a 3D printed object made out of foamed plastic—it was like seeing the future! My team and I have been pioneering with all these advancements, helping to create new applications and industries for foamed plastics.

The car industry loves foamed plastics because they're lightweight and excellent thermal retention. I've been able to work on some cool projects that put foamed plastics in automotive interiors to make them increased comfort and improve fuel efficiency.

One of my fave projects was making a instrument panel out of foamed plastic that reduce vehicle weight by 20%. It's really cool to see how these materials can have a significant impact in lives of individuals.

The structure market has also been using expanded plastics because they're positive at keeping things warm and strong. I've worked on tasks that used expanded plastics to keep heated structures, which saved energy and made them more efficient.

One time I worked on a project that put a foamy plastic cover on a big structure, which helped decrease the energy expenditures a lot. It feels positive to know that what I'm carrying out is aiding to make a improved environment.

The expanded plastics market is always changing, bringing new obstacles and chances. Working in this sector has taught me to keep a optimistic mindset and deal with changes.

By keeping up with the information and being adaptive, we can deal with issues and grab new opportunities. My team and I have been recognized for coming up with innovative methods to do things in this market, and we're always trying to do more with expanded plastics.

If you want to learn additional information on Cellular structureed Polymer materials, explore these references:

- “Foaming Plastics: Components, Manufacturing, as well as Usage” authored by Author Author's name J. L.

White

- “The Principle of Foaming Plastics” written by Author Author R. W. Houghton's work

- “Foaming Plastics Sector - International Field Study, Magnitude, Proportion, Expansion, Patterns, as well as Prediction from 2021 to 2027” by Sectorsas well asSectors

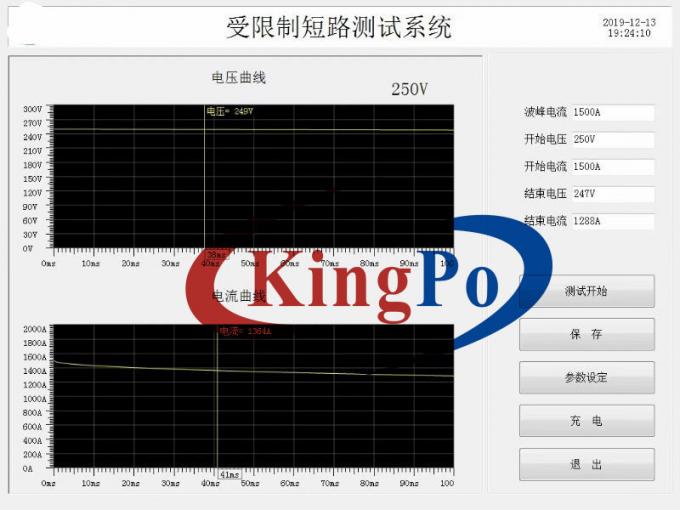

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability