Buy Top-Notch Textile Tensile Testing Machines

You know, making textile tension testing equipment, we totally get how crucial it is to give people high quality gear for all sorts of needs. Alright, in this piece, we're gonna take a gander at the five major requests we get from the textile industry, and how we're handling 'em to ensure our customers are satisfied.

1. Accurate and Reliable Results

3. Customizable Testing Parameters

5. Environmental Sustainability

Our peeps mostly just want their results to be exceedingly accurate and reliable. So, we've put our smart thinking to work and made testing machines that use the latest tech to give extraordinarily precise measurements. These machines are set up to minimize errors and consistently provide consistent outcomes, extremely important for making sure stuff in the textile industry is high quality.

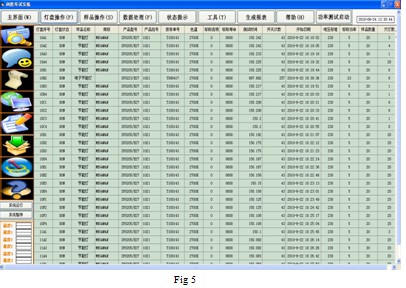

Take our test equipment, for instance—they got this slick closed-loop control system that monitors closely on and tension adjustment while the test is going on. It keeps things uniform during the whole test, so you get results that are more dependable and accurate. We have also incorporated sophisticated sensors and data collecting systems to collect and examine the data instantly, providing our clients with thorough reports that help them make well-informed choices.

Lots of peeps also want things to be intuitive. We know not all individuals are professionals in testing textiles, so we made these machines super user-friendly with a friendly interface. They're got a touch interface that makes it easy to mess with various configurations and perform tests.

And we've got all sorts of instructional materials and user manuals to help out clients. These tools help everyone understand how to use the machines and interpret those results. It's not just about making life easier; it also cuts down on mistakes and boosts productivity big time.

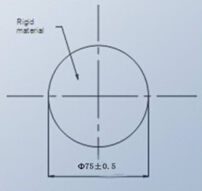

Fabric materials can be varied, so distinct tests need to be done for each one. So to keep things adaptable, we let clients change the settings on our machines for their specific needs. Clients can adjust settings like stress and velocity to fit their distinct testing requirements.

This means clients can run all kinds of tests, from simple tensile strength assessments to complex tests that simulate real-life scenarios. And by making these settings customizable, we make sure our clients obtain data they need to go with their products.

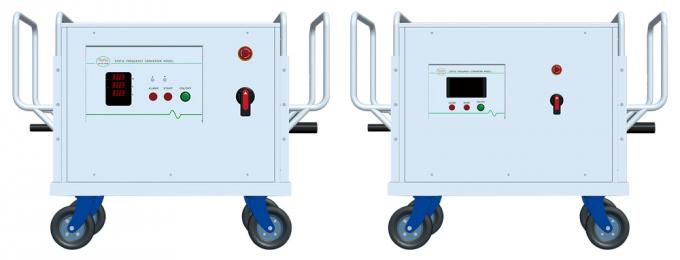

These machines are a important issue for clients, so they want 'em to endure over time and be robust. So we use premium components and stuff in building these machines. These things are designed for durability, even when they're subject to rigorous testing and endured heavy usage.

Not just the materials, but we perform a comprehensive inspection prior to dispatching these. This means each and every machine meets our stringent standards by the time it's delivered to our customers. We stand behind our products with a thorough warranty and post-sales assistance, affording our clients reassurance.

As an accountable manufacturer, we are committed to environmental sustainability. Our textile tensile strength testing equipment are engineered to be energy-saving and reduce waste production. We use eco-friendly materials and processes in the production of our equipment, and we prompt our customers to embrace environmentally friendly approaches in their testing processes.

By focusing on environmental sustainability, we not only contribute to a more sustainable earth but also aid our clients in cutting their operational expenditures. We think It is extremely significant to consider the ecological impact. It is crucial for our clientele and our operations to maintain sustainability.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview