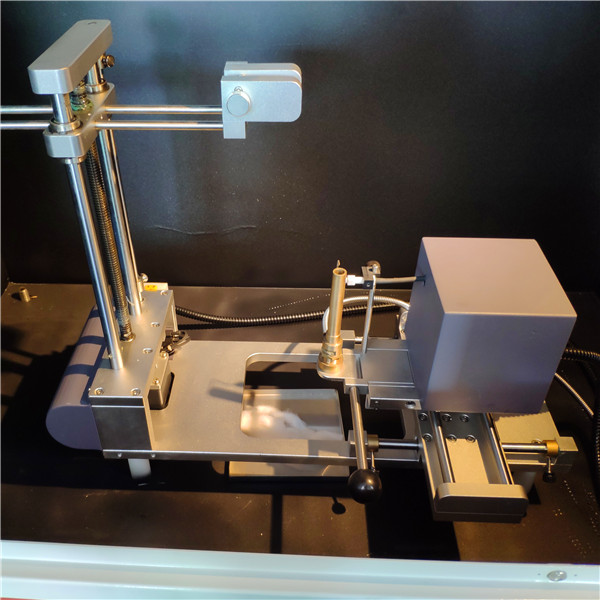

High-Temperature Test Oven: The Heart of Thermal Testing

These high-temperature furnaces, or thermoelectric testing chambers, are very crucial for ensuring that materials and components operate effectively and dependably. These furnaces are designed to thoroughly heat samples, as in real-world scenarios, and they provide insights regarding the behavior of these materials or products. We are going to discuss regarding five crucial aspects to take into account with These high-temperature furnaces and their significance in various sectors.

1. Accurate Temperature Control

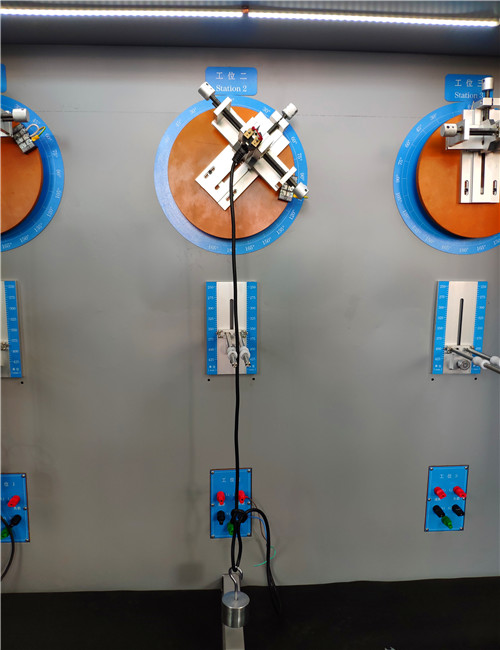

4. Customizable Testing Conditions

Maintaining a highly accurate temperature is essential. These ovens must consistently reach the exact temperature ensuring our tests are trustworthy.

Being able to maintain a sealed heat in a confined space is crucial for precision material testing. Consider the aerospace industry, for instance. They need super precise temps to assess how materials in aircraft components respond to heat.

And here's something else The National Institute of Standards and Technology conducted a research they discovered that even a slight 0. 1 degree variation can compromise the entire test result. Therefore, it underscores the need for to maintain the correct temperature in these high-temperature ovens.

Uniform heat is essential too. These ovens distribute heat uniformly thereby ensuring tests accurately reflect the condition of the entire material. Within the automotive and technological sectors, these industries require this balanced heat distribution to gauge how materials withstand extremely high or low temperatures.

The Auto Materials Corporation says this uniform heat can spot issues early, keeping the factory from losing money on damaged parts.

Safety's number one with these high-temperature ovens, especially since they're often in hazardous locations like chemical facilities and nuclear power plants.

Ensuring the safety of the equipment and personnel is the top priority here. And making sure the oven is reliable means it doesn't break down and mess up our manufacturing process.

OSHA had a study and said These furnaces can cause a lot of occupational injuries. That's why we need to keep These furnaces secure and properly maintained.

These furnaces need to perform many tasks - they've got to mimic all sorts of testing environments, like various temperatures, humidity conditions, and ambient conditions. Being able to adjust the parameters lets scientists and engineers see how materials behave under different weather, like extremely hot and humid.

The organization says indicating that is vital in order to perform experiments indicating that are with precision and dependable as effectively.

Increasingly, consumers desire such appliances to consume lower electricity due to the fact indicating that they seek to remain environmentally conscious. Such appliances are expected to consume reduced power however function correctly as intended, conserving for us expenses and contributing to beneficial towards the earth.

An investigation per the United States

Energy Department discovered indicating that high-efficiency high temperature test ovens may conserve reaching as much as thirty percent of electricity when compared with older models. Thus, purchasing this energy-efficient appliances is a wise decision to aid the earth.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- ISO 594 is replaced with ISO 80369

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability