Tensile Testing Plans for Enhanced Materials Quality

I've been doing a lot of work in the tensile testing field for a few years now. I've picked up a bunch of insights on how it improves material quality. I wanna share my experiences and some cool stuff I've learned about key concepts in tensile testing.

Material characteristics are pretty key when it comes to understanding tensile testing. That means stuff like tensile strength, elasticity, yield strength, and how much it stretches before it breaks.

When I'm doing tests, I notice how things like temperature, humidity, and how it's made can affect these properties. Like, I remember a time when I was testing a new kind of high-strength steel and we had to test it at various temperatures. Through analyzing the data, we were able to tweak the material composition and how it's made.

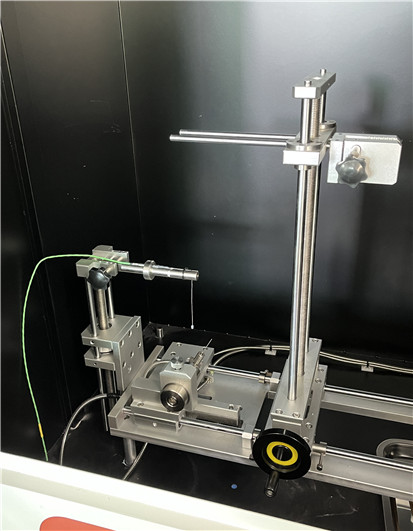

The gear you use for testing is also really important. When I use these testing machines, I know it is important to pick the right one for the material, like using an Instron and MTS machine.

You gotta keep the equipment calibrated and up-to-date to get accurate, reliable results. I once had to test a lightweight composite and the machine just couldn't handle the force needed. We had to switch to a more robust machine, and it gave us more accurate results.

There are different ways to test materials, like using a constant cross-head rate or a constant load speed. I've noticed that what test method you use can really affect the results.

For example, you'd use the constant cross-head rate for fragile materials, and the constant load speed for extensible materials, like metals. I remember a time when we had to test a plastic material's capacity to stretch. Using the constant load speed method, we could see how the material stretched and how it responded under stress.

Examine the data is the final step in the testing process. I have learned that the key for grasping the data consists of knowing how the material responds under pressure.

Employing statistics and software applications, I am able to examine the data and deduce what characteristics the material possesses. This is particularly important for intricate materials such as composites. I was involved in a project in which we examined a carbon fiber reinforced polymer's capacity to elongate. The data assisted us identify weaknesses that may exist and proposed methods to enhance the design.

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-3 Test Equipment LIst

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability