Vickers Hardness: The Comprehensive Guide

You ever think about What to evaluate how hard So,,,mething is? Well, Vickers hardness is a super popular method to determine how hard metals, ceramics, and similar materials are. And it is quite interesting because it doesn't mess up the thing you're testing, And it is very accurate. Okay, let's dive into the entire process with Vickers hardness and look at So,,,me common questions people have it.

What's Vickers hardness, by the way?

So, how do you measure Vickers hardness?

So, what's so great about Vickers hardness?

What's not so great about Vickers hardness, though?

So, how do you make sense of the Vickers numbers you get?

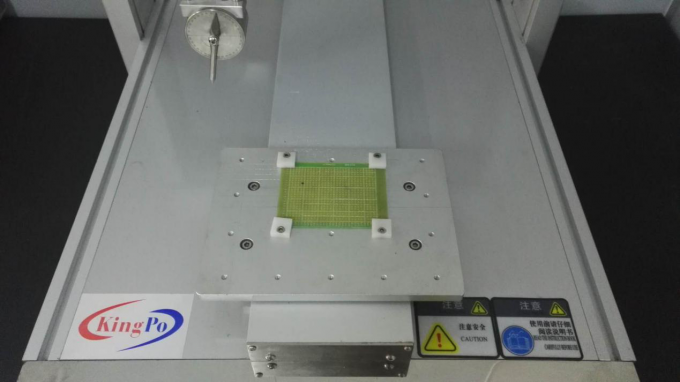

Vickers hardness is a method of determining how hard something is by inserting force onto it with a diamond indentor. Once the penetration is created, you use the size to compute the hardness value. This technique is known for its great precision and is widely used in numerous sectors.

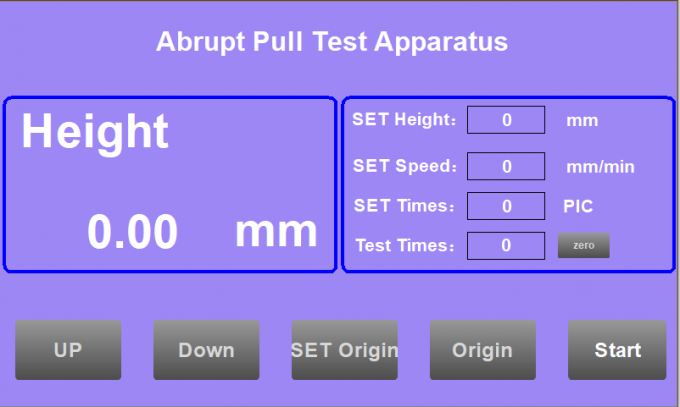

Well, measuring it is kind of a process. First off, you use a diamond device that's got a particular shape and size to create an impression on the surface. Then, you put more pressure on the diamond thingy for a period of time. Once the pressure is released, the indent size is measured using a magnifier, and the Vickers hardness value is calculated via the following equation:

There are a bunch of benefits about testing stuff with Vickers hardness. First off, it doesn't break the thing you're testing, which is excellent.

It's super precise, too, and you can trust the findings, which is important for making sure things are good standard. And it works for all sorts of substances, from ferrous materials to ceramic materials and even polymer materials.

Even though it's really valuable, Vickers hardness has a few drawbacks. It can take a while, especially if the surface is all irregular or if you're testing a large sample.

Also, you need individual who knows what they're doing to make sure you get good findings. And sometimes, additional tests might be better depending on what you're actually application for.

You consider the number you get and compare to something like a chart or a computer database. This informs you about the toughness of the material and if it's suitable for its intended use. Just remember, the Vickers number doesn't tell you everything about how strong the material is. It simply provides an understanding of how challenging it is to indent the material.

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability