Maximizing Purchase Power with Acceleration Shock Testers

I'm an engineer in material testing. I've always been really into what acceleration shock testers can do. They're extremely crucial for making sure products can withstand really severe and rapid stresses. I'm going to immerse oneself in the whole field of shock testing equipment. I'll discuss why they're important, how they're used, and some of the stuff I've struggled with using them.

Collision testing is a significant aspect in stuff like automotive manufacturing, aerospace vehicles, and structures. It's extremely significant. As a material scientist, I know that we must ensure we can evaluate the functionality of items in actual conditions in order to produce reliable products.

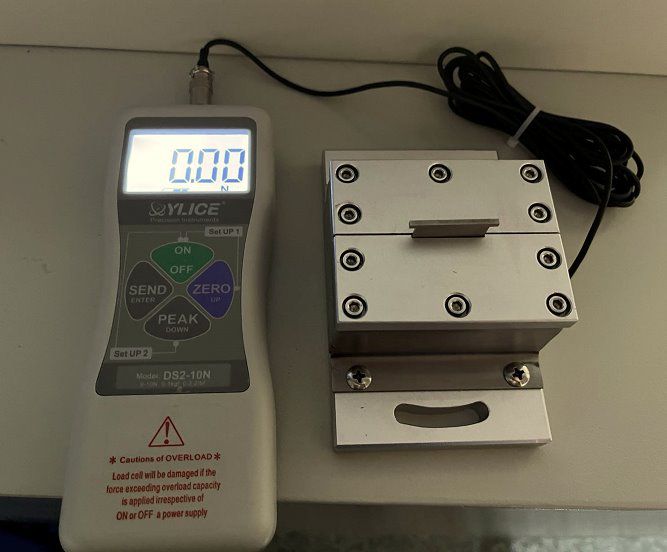

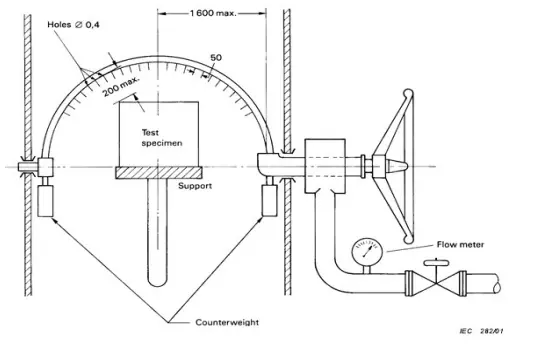

A shock testing device enables us to provide materials a very quick, strong impact, just like they'd get during their use. Upon our knowledge how well a material withstands stress, we can select the appropriate material for the task.

There is another significant aspect shock testers do well, that enables us to observe how materials behave while they are in motion. Shock testers let us see how materials behave when they're put under moving stress, which is essential for understanding how they will perform in dynamic conditions.

I have experienced a considerable amount of difficulty understanding how to measure and understand how materials respond while they are moved. But if you have the appropriate equipment and you are well-informed, you can gain significant insights into how materials may fail or what they are good at.

Inspecting how perform in various climates and stuff like that is super important for figuring out if they'll last. You can get shock testers that are fully prepared for various climates, like extreme temperatures and moisture, and etc. , so you can observe a material does. And I've found out that when combined, you can detect issues that wouldn't reveal with just standard testing.

One of the favorite aspects of my job is picking the right material for the job. Shock testers aid me in determining how materials perform in challenging conditions, therefore I am able to choose the best one for the job. I've seen that getting the right material really makes a difference in how durability and performance a product will operate.

By employing these shock testers has been extremely useful. It's taught me to comprehend how materials behave in extreme conditions. These testers have become a essential tool for me. They really assist me select the most suitable materials and make quality designs. And as technology advances, I'm excited to see the future advancements for impact testers and how they will assist us make more robust materials.

1. ASTM International.

(2021). Testing Standards for Impact Testing of Specimens without Notches and with Notches of plastics. Accessed at https://www. Astm. Org/Standards/D3767. Htm

2. ISO.

(2017). Impact Properties of Plastics – Assessment Method. Accessed at https://www. Iso. Org/standard/63589. Html

3. SAE International.

(2020). Suggested Procedure for Impact Testing of Materials. Accessed at https://www. Sae. Org/standards/details/j2523_202003/

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability