Falling Weight Tester Mastery: A Personal Journey

So, I'm an engineer who really loves ensuring things are up to snuff. I've gotten to dive into this cool world of drop impact testers. The devices are extremely crucial for ensuring items are strong and safe. Over the years, I've run into a bunch of fascinating information about the devices, and they've taught me a lot.

3. Data Analysis and Reporting

4. Equipment Maintenance and Upgrades

The major concern with the devices is ensuring they're exceptionally precise. Adjusting the devices it's not merely a single event; it's a continuous task.

I remember this difficult project our group had where we needed impossibly precise drop heights. After extensive modification, we finally achieved the correct outcome, and it was the most essential priority for the project.

Developing robust testing plans is a must for enabling successful outcomes. I've made specific testing plans for a varied selection of materials and stuff.

You gotta know what the primary features of the material, potential failure zones, and the fundamental level of resilience. We collaborated with the team and came up with detailed and thorough plans that everyone uses.

Compile data from these tests is just the start. The real challenge is figuring out what what it all signifies and crafting a detailed report.

I've got pretty good at examining the data from these tests and presenting it in a manner that's conspicuously insightful and useful. It has been extremely fulfilling when our insights contribute make products enhanced and safer.

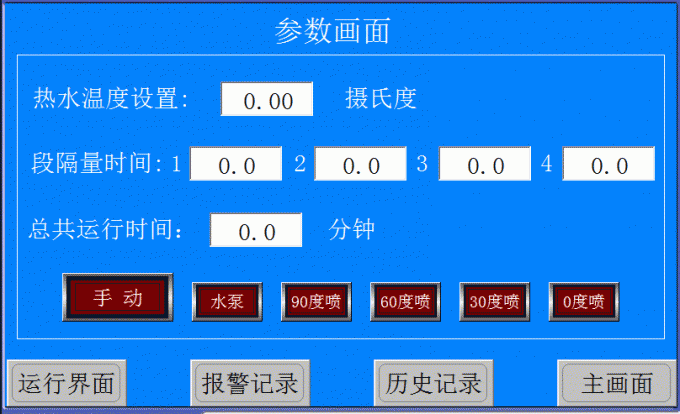

Keeping our testers in the best condition and updating them is a significant aspect of our daily tasks. Regular maintenance keeps the gear going strong and on the money. I've worked on a few upgrades, like installing new technology for improved testing.

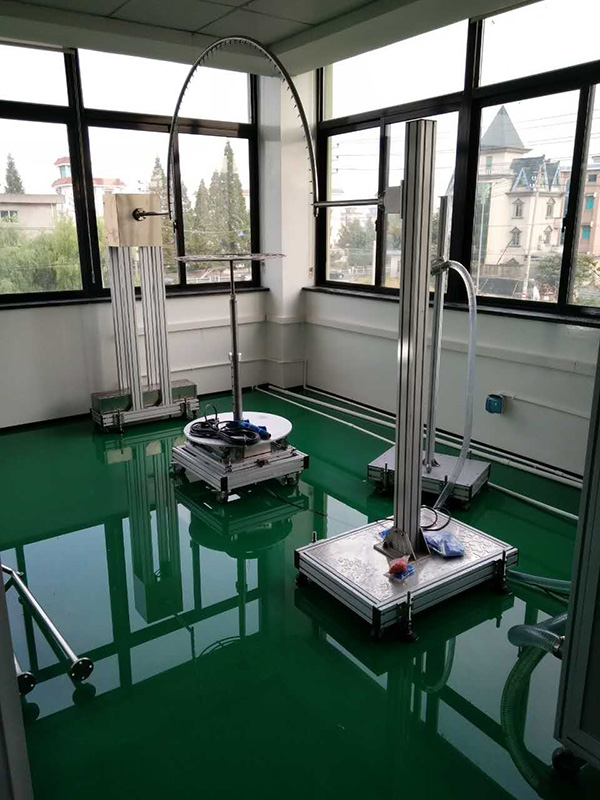

These testers are used all over the place, from devices to automotive parts. I've had the chance to work with clients from different fields, each bringing its own set of difficulties and opportunities. This has helped me learn a lot and become a more adaptable engineer.

Working with these testers has been a blend of challenging and beneficial. I've realized that being extremely precise, working together, and continuously striving for improvement are what make this field work. As I keep advancing in my profession, I'm excited to take on new challenges and contribute to enhancing the quality assurance process.

Additional information and interesting material to read, explore these:

- ASTM - www. Astm.

Org

- International Organization for Standardization - they are located at www. International Organization for Standardization. Org

- American Society for Quality - they're at www. American Society for Quality. Org

Keep in mind, since this piece is useful, always consult with experts regarding your particular scenario.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

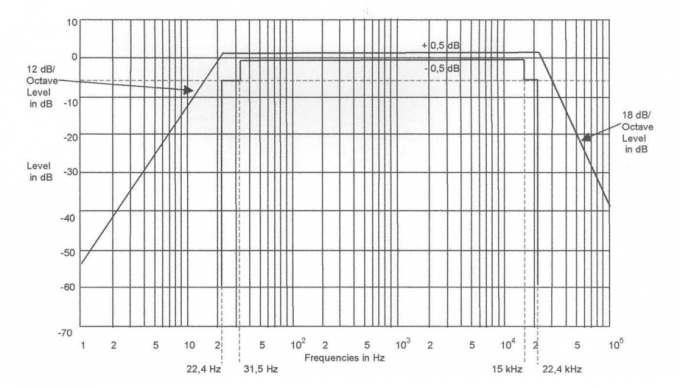

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst